Custom acrylic paint pens manufacturer Jaredrise recommends testing samples before placing bulk orders to minimize product-quality risks and gather reliable performance data.

A clear, step-by-step testing protocol ensures the sample reflects stable manufacturing standards, not just a one-off prototype.

You can test custom acrylic marker samples from China by first understanding why testing is necessary before placing a bulk order

Testing matters because sample performance is the only reliable indicator of whether a China acrylic marker supplier can maintain consistent ink quality, nib durability, and color accuracy across real production batches.

Many buyers have faced issues like uneven flow, premature nib wear, or leaking barrels after skipping the sample-validation phase.

By understanding the common risks upfront, you can focus on tests that reveal the true stability of a manufacturer’s formula and assembly process.

Ink formulation inconsistencies show up quickly when pigment ratios vary between batches

Acrylic markers rely on stable pigment-to-resin ratios to deliver even coverage, and variations in these ratios often cause watery strokes, streaking, or sudden pigment surges.

During procurement audits, inconsistent ink behavior is one of the most frequent issues observed in small and mid-size factories.

Nib deformation helps you identify whether the supplier uses low-density fiber cores

When nibs lose shape early, it indicates that the material is not designed for repeated pressure or continuous use.

This early wear-out becomes a major problem in bulk orders intended for professional art or crafts, where markers need to survive extended strokes.

Barrel leakage usually signals insufficient sealing pressure or unstable filling lines

Many acrylic-marker issues arise from weak joining pressure or irregular filling processes.

Leakage rarely improves in bulk production, which is why early detection through sample testing helps avoid large-scale product damage during shipping.

You can test acrylic marker samples effectively by following a structured step-by-step evaluation method

A clear method allows you to identify performance issues early by testing core aspects such as ink flow, opacity, drying time, nib strength, leakage resistance, and documentation accuracy.

These tests simulate real user scenarios and reveal the true stability of a supplier’s acrylic formula.

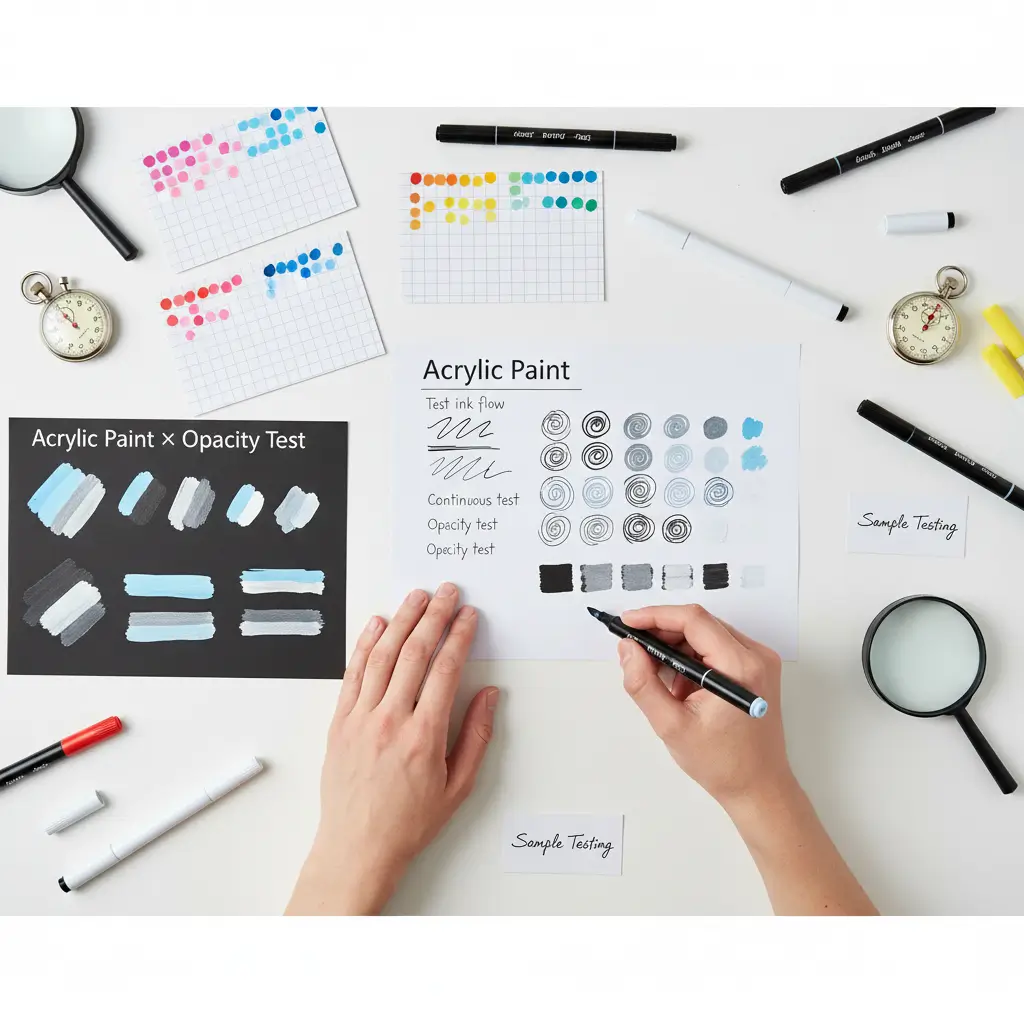

Step 1 — Test ink flow by drawing continuous lines for 10–15 seconds

The continuous-line test exposes sputtering, clogging, or pigment dropouts. Stable acrylic formulas should produce uninterrupted coverage on both smooth and porous surfaces.

Step 2 — Test opacity using both white and black paper

Opacity testing helps determine pigment density.

High-quality markers typically achieve 70–90% single-layer coverage even on darker surfaces, which is essential for craft and DIY applications.

Step 3 — Measure drying time using a simple stopwatch

Proper drying ensures layering without smudging.

Most stable water-based acrylic formulas dry within 15–25 seconds under room conditions.

Longer drying usually indicates excess moisture or reduced resin content.

Step 4 — Test nib durability using 150–200 back-and-forth strokes

Durable nibs resist splitting and fraying under pressure.

This simulation helps you understand whether the nib can withstand real-world use, especially for continuous coloring or outdoor surfaces.

Step 5 — Test leakage resistance by shaking and storing the marker upside down

Leakage tests reveal pressure imbalance or insufficient sealing—both key weaknesses that often worsen in mass production.

A reliable marker should remain clean after agitation and a two-hour inverted test.

Step 6 — Compare the marker’s performance with the supplier’s technical sheet

Comparing real results with the supplier’s specs helps you identify discrepancies.

Variations between documentation and sample performance often indicate unstable production processes.

You can increase accuracy by running extended reliability tests that simulate long-term use

Extended tests reveal how markers behave under various conditions, helping you forecast long-term user experience and identify weaknesses that short tests may miss.

Test climate stability by exposing samples to heat, cold, and humidity

Temperature fluctuations can cause ink viscosity changes and pressure inconsistencies.

Monitoring the marker after environmental stress helps determine shipping reliability.

Test UV fade resistance by placing color swatches under light for 48–72 hours

UV exposure helps you understand whether pigments maintain their color integrity under direct sunlight.

High fade levels suggest the pigments are unsuitable for outdoor or high-light applications.

Test storage reactivation by leaving markers unused for several days

A high-quality acrylic marker should restart smoothly with minimal shaking, indicating stable formulation and good sealing.

Poor reactivation suggests clogging issues.

You can verify the reliability of a China acrylic marker supplier by checking compliance, QC documentation, and production transparency

Supplier verification ensures that samples represent actual production capabilities rather than selectively prepared units.

This step is essential before approving any custom or bulk order.

Request certifications such as ISO9001, EN71-3, and ASTM D-4236

Certifications confirm production control, safety standards, and formula compliance.

Reviewing certification details also helps validate the reliability of the factory.

Ask for QC reports from multiple production batches

Batch reports reveal how frequently issues occur in real production.

A reliable supplier should provide inspection data across different periods instead of a single ideal sample.

Request production videos showing ink mixing, barrel assembly, and nib installation

Production transparency helps you confirm whether the facility uses automated filling lines or manual processes, which affects stability in bulk shipments.

You can evaluate samples more objectively by using a structured testing checklist

A checklist helps ensure you do not overlook key performance factors, making your evaluation consistent and repeatable across suppliers.

- Include ink flow, opacity, drying time, nib life, leakage resistance, color accuracy, and UV stability in your checklist.Covering all essential performance indicators provides a complete quality profile before committing to a supplier.

- Include documentation checks such as MSDS, pigment data sheets, and batch labeling.Documentation helps confirm long-term stability and verifies that materials used match what was promised.

- Compare results across multiple suppliers using the same scoring format.A consistent scoring system allows fair comparison and reduces subjectivity during supplier selection.

You can rely on Jaredrise when testing custom acrylic marker samples because the company provides transparent data and consistent sample quality

Jaredrise supports buyers by offering sample sets drawn from real production batches, detailed technical sheets, material sourcing transparency, and optional independent inspections.

These practices help ensure that testing reflects real production behavior.

- Jaredrise provides unfiltered samples taken from ongoing production,this gives buyers a true representation of quality stability rather than idealized factory samples.

- Jaredrise supports sample testing with measurable data such as opacity ratings, nib endurance, and average drying times.Providing quantifiable metrics helps buyers evaluate performance based on objective data rather than subjective impressions.

- Jaredrise maintains documented pigment sourcing and fiber material traceability.This traceability helps ensure stable performance across repeated orders.

- Jaredrise allows buyers to request third-party inspections or pre-shipment testing.This adds an additional layer of assurance, especially for buyers handling large or recurring orders.

- Jaredrise uses automated filling and sealing lines to reduce leakage risk.Automated sealing improves pressure consistency, which is essential for long-distance shipping.

You can protect your purchasing investment by following a disciplined testing and supplier verification process

A structured process minimizes the chances of receiving inconsistent or defective products, especially in large-volume orders.

By completing sample tests, verifying supplier reliability, and comparing results across multiple sources, you ensure greater predictability in your final procurement.

You can achieve reliable results by selecting suppliers whose samples consistently pass ink, nib, opacity, and sealing tests

Choosing suppliers based on thorough sample testing helps you achieve stable performance in bulk orders.

When paired with transparent partners like Jaredrise, the entire sourcing process becomes more predictable, allowing you to proceed confidently with your custom acrylic marker order.

Conclusion

Testing custom acrylic marker samples before placing an order is a critical step that helps buyers confirm ink quality, durability, safety compliance, ergonomic comfort, and supplier reliability.

A structured evaluation process—covering physical inspection, ink performance, durability, compliance, and packaging—provides clear insights into whether the sample represents stable manufacturing standards.

Comparing multiple suppliers and verifying production capabilities help ensure the markers will remain consistent across future bulk orders.

Buyers looking for dependable acrylic marker manufacturing can benefit from working with a supplier like Jaredrise, whose QC systems, documentation standards, and sampling methods support predictable long-term cooperation.