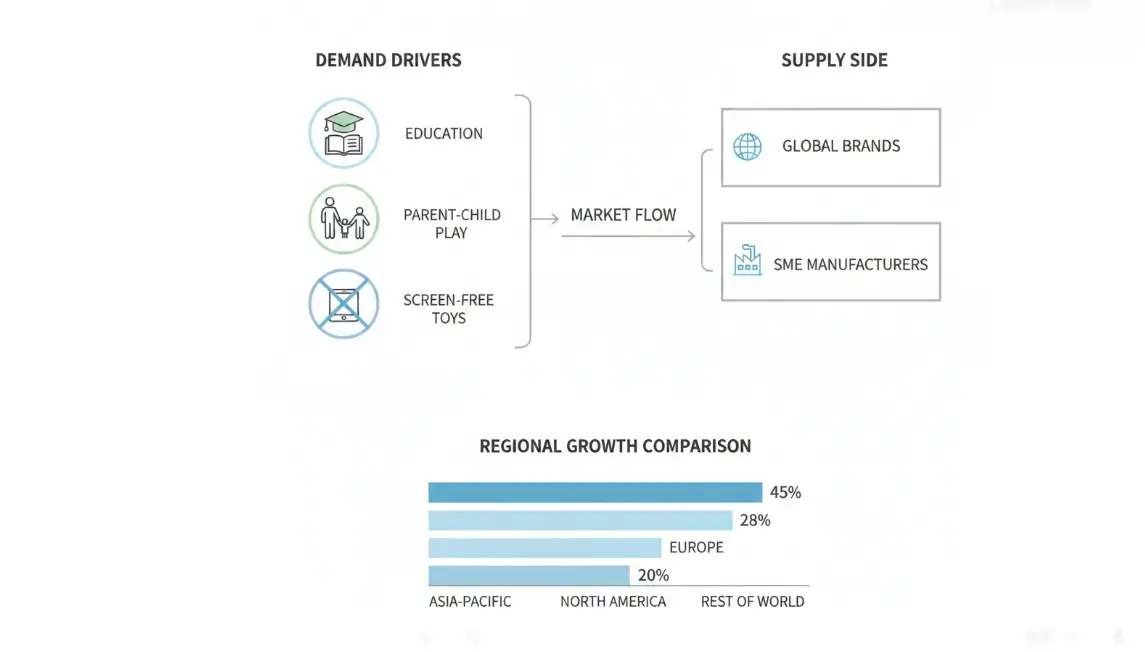

The Magic Water Elf Kit market is expanding steadily, driven by demand for safe, educational, hands-on toys for children aged 3–10 and parental preference for screen-free activities.

Growth is strongest in Asia-Pacific, while North America and Europe remain mature, compliance-driven markets. Competition is high due to low production barriers, but differentiation exists through themed designs, educational integration, eco-friendly materials, and enhanced durability.

Product viability depends on strict material specifications, controlled solidification performance, and child-safe physical dimensions. Regulatory compliance is mandatory, including EN 71 (EU), ASTM F963 and CPSIA (US), ST standards (Japan), and GB 6675 with 3C certification (China).

Effective sourcing requires structured sample evaluation, third-party safety testing, consistency checks, and contract-based quality accountability.

Manufacturers with integrated production, certification experience, and export capability reduce regulatory and supply-chain risk. Market trends favor environmentally compliant materials, diversified gameplay formats, and tighter global safety enforcement.

Magic Water Elf Kit Market Overview & Product Opportunity

The Magic Water Elf Kit, as a popular hands-on toy for children, has witnessed steady growth in the global market in recent years.

This growth is driven by the rising demand for quality parent-child interaction products and the emphasis on cultivating children’s hands-on abilities and creativity.

Geographically, the market is dominated by regions such as North America, Europe, and the Asia-Pacific, with the Asia-Pacific region showing the fastest growth rate, fueled by its large child population, upgrading consumption concepts among young parents, and booming e-commerce channels.

From the demand side, the core consumer groups are families with children aged 3-10. Parents are increasingly willing to invest in safe, educational, and entertaining toys that reduce children’s reliance on electronic devices, making Magic Water Elf Kits a preferred choice for daily parent-child activities and holiday gifts.

From the supply side, the market is composed of a mix of well-known global toy brands and numerous small- and medium-sized manufacturers.

The low initial investment in production has led to intense market competition, but products with unique designs, safe materials, and rich gameplay still hold core competitive advantages.

Currently, the market is characterized by “diversification of gameplay” and “segmentation of user groups.

Basic kits with simple molding functions are gradually being supplemented by upgraded versions with themed designs, extended accessories, and educational elements, further expanding market penetration.

Product Opportunity

Against the backdrop of market upgrading, several key product opportunities have emerged for Magic Water Elf Kits:

- Themed and IP-Bound Kits: Collaborating with popular children’s IPs (such as animation characters, fairy tale themes, and cartoon images) to launch customized kits can significantly enhance product appeal. For example, designing water elf molds and colorants based on IP characters, and adding exclusive collectible cards or story manuals to stimulate purchase desire among fans.

- High-End and Eco-Friendly Upgrades: With the increasing emphasis on children’s health and environmental protection, there is clear demand for high-end kits using food-grade colorants, non-toxic silicone molds, and degradable packaging materials. Functional upgrades such as glow-in-the-dark colorants or waterproof finished products can also create premium differentiation.

- Educational Integrated Kits: Integrating scientific knowledge (such as the principles of material solidification, color mixing, and mold design) into the kit, matched with teaching guides for parents and teachers, positions the product as an “early education hands-on tool,” tapping into the demand of kindergartens, early education institutions, and family education scenarios.

- Interactive and Collaborative Sets: Launching multi-person collaborative kits (suitable for siblings or friends to play together) with shared large molds and multiple color sets, and adding interactive elements such as “elf family building” or “scene layout” extends gameplay time and enhances parent-child and peer interaction value.

- Cross-Channel Customization: Developing lightweight, portable mini-kits for convenience stores and vending machines, and large gift sets for online e-commerce platforms and offline toy specialty stores, adapts to different sales channels and expands market coverage.

Magic Water Elf Kit Specification & Compliance

The specification of Magic Water Elf Kits mainly covers product composition, material standards, physical parameters, and performance requirements, ensuring product safety, stability, and playability:

Product Composition

A standard Magic Water Elf Kit typically includes: 1-3 bottles of water-soluble colorants (each 30-50ml), 5-10 sets of silicone molds (different shapes such as animals, plants, and elves), 1-2 mixing cups, 1 dropper or syringe, 1 drying tray, and 1 instruction manual.

Upgraded versions may add accessories such as decorative stickers, scene mats, and storage boxes.

Material Requirements

- Colorants: Must be non-toxic, water-soluble, and comply with food contact grade standards. No heavy metals (lead, mercury, cadmium, etc.) exceeding the limit, no irritating odors, and good color fastness (no fading after solidification).

- Molds: Made of food-grade silicone or PP material, Shore hardness 50-70A, flexible, easy to demold, high temperature resistance (80-100℃), with no burrs or sharp edges.

- Auxiliary Tools (mixing cups, droppers): Made of BPA-free PP or PE material, smooth surface, no leakage, suitable for children’s small hands.

- Packaging: Non-toxic, environmentally friendly cardboard or plastic, structurally strong to prevent damage during transport; size suitable for storage and display.

Physical and Performance Parameters

- Solidification Time: The colorant should solidify into a soft, elastic elf shape within 1-3 hours at room temperature (20-25℃) without deformation or cracking.

- Product Size: Finished elf products generally 3-8cm in length/height; avoid excessively small parts to prevent accidental ingestion by children under 3 years old.

- Durability: Solidified elf products should be flexible, resistant to tearing or breaking, and waterproof (can be soaked in water for extended periods without dissolving).

- Operability: Colorant has appropriate fluidity for easy shaping with a dropper; molds are easy to clean and reusable.

Compliance Requirements

As a children’s toy, Magic Water Elf Kits must comply with the toy safety regulations of the target market to ensure legal sales and user safety. Core compliance standards include:

International Compliance Standards

- EU: Comply with EN 71 series standards (EN 71-1: Mechanical & Physical Properties, EN 71-2: Flammability, EN 71-3: Migration of Certain Elements, EN 71-9: Organic Chemical Compounds) and obtain CE certification.

- United States: Comply with ASTM F963 and CPSIA, strictly limiting lead and phthalates; require third-party testing and certification.

- Japan: Comply with ST 2016 (Safety Standard for Toys), covering mechanical properties, chemical substances, and flammability; obtain ST mark certification.

China Domestic Compliance Standards

Comply with GB 6675 series standards (GB 6675.1: General Requirements, GB 6675.2: Mechanical & Physical Properties, GB 6675.3: Migration of Certain Elements, GB 6675.4: Flammability, GB 6675.5: Organic Chemical Compounds).

Products sold in China must bear the 3C certification mark (for toys under compulsory certification).

Additional Compliance Requirements

- Labeling Compliance: Packaging must clearly mark product name, manufacturer information, age group (e.g., “Suitable for 3+ Years Old”), safety warnings (e.g., “Keep small parts away from children under 3 years old”), and certification marks (CE, 3C, etc.).

- Chemical Substance Limits: Strictly control harmful substances such as heavy metals, phthalates, formaldehyde, and VOCs according to latest regulatory requirements.

- Production Compliance: Production must follow GMP standards, maintain a complete quality control system, and retain raw material inspection reports and finished product testing records for traceability.

- Eco-Friendly/Educational Products: Optional certifications (organic material certification, ISO 14001 environmental management) enhance market credibility.

Magic Water Elf Kit Sample Evaluation & Ordering Process

Sample evaluation is a core step to ensure product quality and market adaptability, focusing on safety, functionality, and production consistency. The evaluation content and steps are as follows:

Core Evaluation Indicators

- Safety Compliance: As a children’s toy, the Magic Water Elf Kit must meet international and national safety standards. Conduct chemical testing according to EN71 (EU Toy Safety Standard) and GB 6675-2025 (China National Toy Safety Standard, effective November 2026). Key items include detection of heavy metals (lead, mercury, cadmium, etc.), toxic chemical release from plastics and pigments, and colorant fastness to prevent risks from ingestion or discoloration. Physical performance tests should also be conducted on soluble capsules to check pressure resistance, preventing rupture or leakage, and verify filling integrity to avoid quality defects.

- Functional Experience: Test the molding effect of the water elf—whether it forms a complete, stable shape within the specified time, consistency with the mold design, and resistance to deformation or damage after drying. Evaluate operability: whether molds are easy to demold, whether tools are user-friendly for the target age group, and clarity of instructions.

- Production Consistency: Obtain multiple sets of samples from the same batch to check consistency in color, texture, and accessory configuration, avoiding variations in mass production due to unstable processes.

Sample Evaluation Steps

First, perform an appearance inspection to ensure packaging integrity, completeness of accessories, and absence of obvious defects.

Next, conduct safety testing using professional equipment or third-party agencies to produce formal test reports.

Then, perform functional verification by simulating actual child usage, recording molding effect, operability, and durability.

Finally, hold a review meeting with procurement, technical, and marketing teams to comprehensively evaluate the sample and propose improvements for any unqualified items.

Pre-Order Preparation

Clarify order requirements: product specifications (mold style, accessory configuration, packaging design), quantity, delivery cycle, and quality standards.

Formulate a procurement budget, including raw materials, production, transportation, and tariffs, with a reserve for potential price or exchange rate fluctuations.

Collect quotations from multiple suppliers, compare price, delivery capacity, and payment terms, and preliminarily screen potential partners.

Order Negotiation & Confirmation

Negotiate key terms with the chosen supplier: unit price, minimum order quantity (MOQ), batch discounts, and delivery schedule.

Clarify quality liability clauses—if goods do not meet standards, the supplier is responsible for return, replacement, or compensation.

Confirm payment method (e.g., 30% advance, 70% balance after acceptance) and sign a formal contract to protect both parties’ rights.

Order Execution & Tracking

Issue a standardized purchase order with product codes, quantities, delivery dates, and acceptance criteria.

Establish an order tracking mechanism with regular production updates and monitor key milestones, including raw material procurement and production completion. Integrate logistics tracking to monitor transportation and coordinate alternatives in case of delays.

Goods Acceptance & Settlement

Upon arrival, conduct batch inspection according to contract requirements.

Verify consistency between purchase order, delivery note, and quality report. Randomly sample goods for safety and functional testing.

Handle defective products according to the contract (return, replacement, or discount). Complete warehousing procedures, settle balances as per payment terms, and archive relevant documents for reference.

Recommended Magic Water Elf Kit Manufacturers & Suppliers (China)

NingBo Jaredrise

Founded in February 2016, Ningbo Jielide Lighting Co., Ltd. (NingBo Jaredrise) is a joint-stock company registered in Yinzhou District, Ningbo, Zhejiang, with a registered capital of 1 million RMB. The company manufactures and trades multiple product categories, including lighting, electronics, crafts, daily necessities, toys, and plastics.

It holds import/export qualifications for self-operation or agency of goods and technologies, excluding restricted items.

The business model integrates production and trade, offering one-stop services from production to export for Magic Water Elf Kit buyers.

Core Advantages for Magic Water Elf Kit Supply

- Comprehensive Business Capacity: The company has mature experience in toys and plastic products. Its existing production and supply chain resources cover Magic Water Elf Kit production needs, ensuring raw material stability and product quality.

- Import and Export Resource Advantage: Familiarity with customs clearance, international logistics, and toy safety certifications (EN71, ASTM F963) reduces compliance and customs risks for exporters.

- Sound Regional Industrial Support: Located in Ningbo, surrounded by a complete industrial chain of plastics, electronics, and packaging materials, aiding cost control, faster delivery, and process customization.

Cooperation Suggestions

Clearly specify safety standards, such as EN71 chemical testing and GB 6675-2025 certification, and request relevant reports. Confirm production line allocation and capacity to ensure delivery timelines. Leverage the company’s trade advantages to discuss cooperative plans for international market expansion, including customized packaging for target markets.

Alternative Suppliers (Complementary Options)

- Taizhou Huangyan Haoke Plastic Mould Co., Ltd.: Located in Huangyan District, Taizhou (“hometown of plastic moulds”), specializes in plastic toys and molds. Strengths: mature molding technology, customized mold services, ISO9001 certified quality. Limitation: lacks independent import/export qualification, needs third-party trade cooperation for exports.

- Yiwu Jintai Toys Co., Ltd.: Located in Yiwu International Trade City, experienced in children’s DIY toys. Offers flexible MOQ (as low as 500 sets), suitable for small/medium buyers or trial orders. Provides one-stop export services. Limitation: customization flexibility lower than independent mold manufacturers.

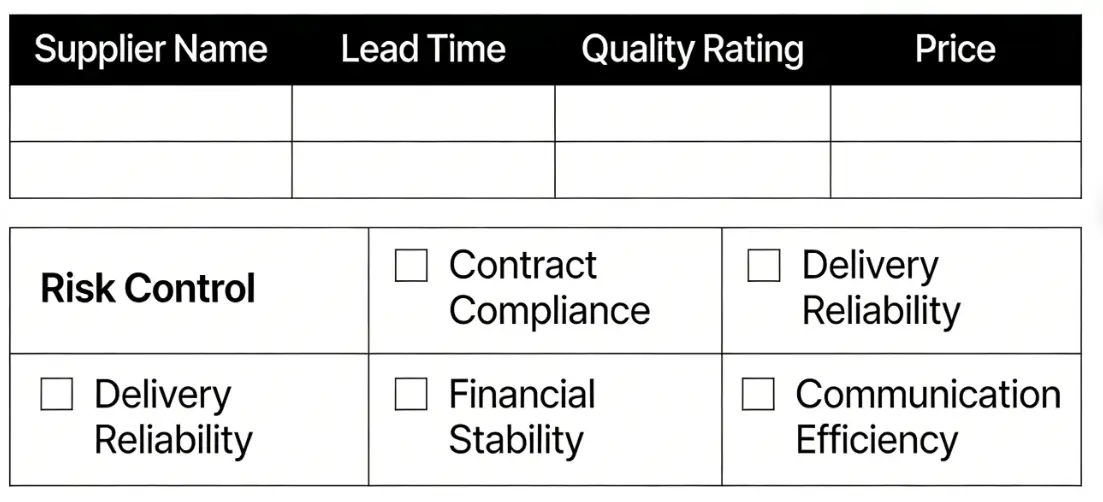

Quality Risk Control

Sign a detailed quality agreement specifying sampling inspection ratio (recommended 3%-5% for large batches), defective product rate (usually ≤0.5%), and handling of unqualified items. Assign on-site inspectors for key production steps, including raw material inspection, pigment mixing, and capsule filling. Establish supplier quality rating systems and link ratings to future cooperation and pricing.

Delivery Delay Risk Prevention

Include delivery deadlines and liquidated damages in the contract (recommended 0.3%-0.5% of total order per day, capped at 5%-10%). Require a detailed production schedule and key milestone confirmations. Suppliers must notify in writing within 24 hours of any issues and propose corrective plans.

Intellectual Property Risk Avoidance

For customized molds, patterns, or packaging, sign IP ownership agreements granting exclusive rights to the purchaser. Ensure suppliers do not resell or use designs for other customers. Check existing products for patent or copyright issues to avoid legal disputes.

Industry Development Trends of Magic Water Elf Kits

- Green and Environmentally Friendly Materials: Increasing demand for eco-friendly and non-toxic materials. Suppliers are using water-based pigments, degradable plastics, and non-toxic colloids. Prioritize suppliers with R&D and production capabilities in environmentally friendly materials.

- Diversified Product Forms: Beyond traditional molding, kits now include luminous, color-changing, fragrant features, or scene combinations (e.g., underwater themes). DIY combined kits allow multiple mold sets to enrich play experience. Discuss innovation with suppliers for differentiated products.

- Strict Safety Certification Requirements: Safety standards are continuously updated globally (e.g., EU microplastic detection, US heavy metal limits). Purchasers should monitor standard updates and ensure suppliers maintain certification compliance for smooth market entry.

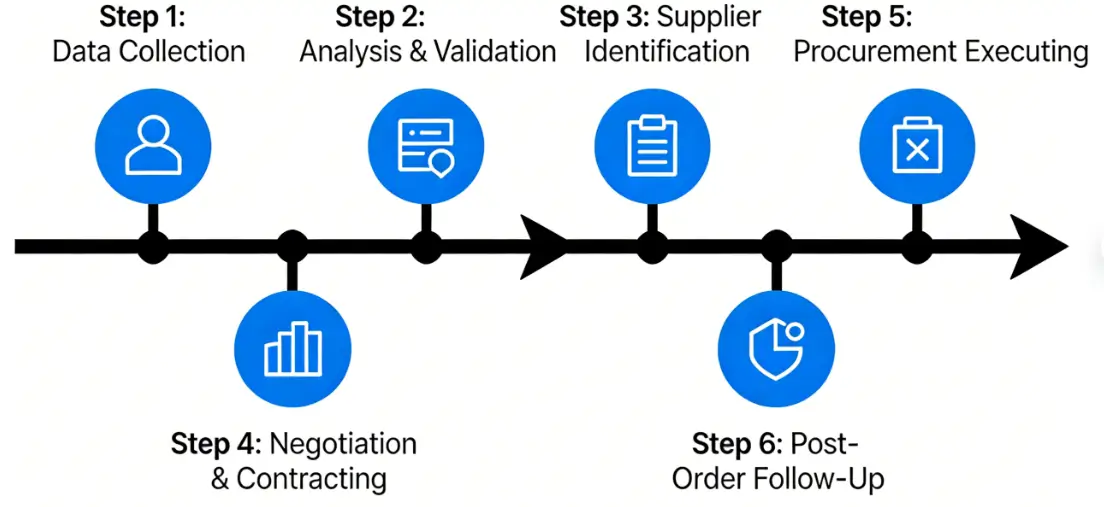

Practical Sourcing Steps for Amazon Sellers

Sourcing is a core factor determining the profitability, competitiveness, and long-term development of Amazon sellers.

A scientific and standardized sourcing process helps avoid risks such as poor quality, high costs, and supply chain disruptions, laying a solid foundation for product listing and sales.

The following are practical sourcing steps for Amazon sellers, covering the entire cycle from demand analysis to post-sales optimization.

Step 1: Clarify Sourcing Requirements Based on Market and Business Goals

1.1 Conduct In-depth Market Research

Sellers should identify target product categories through Amazon’s search, Best Seller rankings, Hot New Releases, and third-party tools (e.g., Jungle Scout, Helium 10). Focus on analyzing product demand trends (seasonal, evergreen, or trending), competition intensity (number of top sellers, review quantity and score), and customer pain points (from negative reviews of competing products, such as insufficient durability, poor design, or incomplete accessories). Pay attention to platform policies, including category restrictions, mandatory certifications (FDA for food contact products, FCC for electronics, CE for Europe), and prohibited product regulations to avoid sourcing non-compliant items.

1.2 Define Product Specifications and Quality Standards

Based on market research, define product parameters including size, material, color, function, packaging, and after-sales accessories. For example, a kitchen utensil should specify food-grade 304 stainless steel, heat resistance, and whether it has a non-slip handle. Establish clear quality standards: no burrs, no leakage, and passing drop tests for Amazon logistics. Document quality indicators for supplier verification and inspection.

1.3 Calculate Cost and Profit Budget

Before sourcing, calculate total costs including sourcing, packaging, international shipping (FBA head-haul), Amazon fees (referral fee, FBA storage), advertising, and after-sales loss (returns/exchanges). Compare with target selling price to determine expected profit margin (20%-40% typical for Amazon products). For example, if target selling price is $50 and non-sourcing costs are $25, the maximum sourcing cost should not exceed $25 to ensure profitability.

Step 2: Screen and Evaluate Potential Suppliers

2.1 Expand Supplier Channels

Obtain potential suppliers through multiple channels to reduce reliance on a single source:

- Online B2B platforms: Alibaba, 1688.com (China), Global Sources, Made-in-China. Support filtering by qualifications, transaction volume, and reviews.

- Offline exhibitions: Canton Fair, Hong Kong Electronics Fair, industry-specific fairs. Allow face-to-face communication, sample inspection, and understanding production capacity.

- Industry referrals: Recommendations from fellow sellers, associations, or sourcing agents (useful for beginners).

- Overseas suppliers: For high-tech or certified products (e.g., European cosmetics), cooperate directly with local suppliers to reduce certification risks.

2.2 Preliminary Screening of Suppliers

Screen suppliers on qualification, strength, and matching degree:

- Check qualifications: business license, production license, certifications, and experience supplying Amazon sellers (FBA compliance knowledge is a plus).

- Evaluate strength: factory scale (employees, workshops), production capacity (daily output, delivery cycle), and QC system (independent QC team).

- Verify matching: ability to produce according to specifications, MOQ within acceptable range, price within budget.

2.3 Conduct Supplier Background Verification

For key suppliers, verify background to avoid unqualified or fraudulent partners:

- Request factory photos, production videos, or arrange on-site inspections.

- Check transaction records, customer reviews, and cooperative cases (including brand experience).

- Use third-party verification platforms (e.g., SGS, Intertek) for credit and qualification audits.

- Communicate with existing customers to understand delivery punctuality, quality stability, and after-sales service.

Step 3: Obtain and Verify Samples

3.1 Request Samples from Multiple Suppliers

Select 3-5 qualified suppliers and request samples. Clearly specify product specifications, quality standards, packaging, and sample delivery time.

Pay sample fees and shipping. Require suppliers to mark sample information (supplier name, batch number) and provide formal quotations (unit price, MOQ, delivery cycle, payment terms).

3.2 Conduct Comprehensive Sample Testing

Test samples according to quality standards:

- Appearance inspection: blemishes, scratches, color consistency, size, weight.

- Functional testing: verify product functions, operation, and service life; perform aging tests if needed.

- Compliance testing: check platform and market regulations, certification marks, non-toxic materials.

- Packaging testing: simulate international transport, check FBA packaging standards.

- Comparative analysis: compare quality, price, design, packaging across suppliers to select the best option.

3.3 Communicate Revisions with Suppliers

Provide feedback for non-compliant samples with photos or videos. Track revisions and request new samples until standards are met. For qualified samples, confirm mass-produced products match the samples in contract clauses.

Step 4: Negotiate Terms and Sign a Formal Contract

4.1 Key Terms Negotiation

Negotiate key points:

- Price: negotiate reasonable price based on sample quality, MOQ, and order volume; clarify inclusions (tax, packaging) and adjustment mechanisms.

- MOQ: reduce for small/medium sellers; flexible MOQ possible for long-term cooperation.

- Delivery cycle: confirm production and latest delivery date; reserve buffer for seasonal products.

- Quality: write standards, inspection methods, and handling of unqualified products into contract.

- Payment terms: T/T, L/C, PayPal. Avoid 100% prepayment.

- After-sales service: define responsibility for quality issues, returns, and exchanges.

4.2 Sign a Formal Contract

Sign a detailed written contract including party information, product details, price, payment terms, delivery, packaging, inspection standards, breach liability, and dispute resolution. For cross-border deals, use bilingual contracts (Chinese and English) and retain all communication records for dispute evidence.

Step 5: Arrange Mass Production and Follow Up on Production Progress

5.1 Pay Deposits and Confirm Production Plans

Pay deposit and request production plan with schedule, raw material procurement, and key production nodes. Provide labels, packaging designs, and certifications as required.

5.2 Track Production Progress in Real Time

Maintain close communication during production. Methods:

- Regular updates via photos, videos, or progress reports.

- Assign dedicated personnel or hire third-party inspectors for on-site supervision.

- Resolve production issues promptly (raw material shortage, design adjustments).

5.3 Conduct Pre-shipment Inspection (PSI)

Verify quality, quantity, and packaging meet contract standards. Use internal team, third-party agency (SGS, BV), or supplier QC under supervision. Random sampling by international standards (AQL 2.5/4.0). Require rework, replacement, or deductions for defects; allow shipment only after passing inspection.

Step 6: Arrange Logistics and Warehousing

6.1 Choose Suitable Logistics Methods

- Sea freight: large volume, low urgency (FCL/LCL), low cost, long cycle (20-40 days US, 30-50 days EU).

- Air freight: small volume, urgent, higher cost than sea, 5-10 days.

- Express delivery: small batch or urgent replenishment (DHL, FedEx, UPS), 3-7 days, high cost.

- FBA head-haul: professional company handles transport, customs, delivery to Amazon warehouses; suitable for sellers unfamiliar with cross-border logistics.

6.2 Handle Customs Clearance and Documentation

Prepare necessary documents: commercial invoice, packing list, bill of lading/air waybill, product certifications (CE, FDA), and customs declaration. Ensure accuracy to avoid delays or fines. Logistics companies or local customs brokers can assist.

6.3 Arrange Warehousing and FBA Inbound

For FBA: generate shipping plan, print FNSKU and carton labels, pack goods per FBA rules. Amazon conducts receiving inspection and shelves goods. For FBM: store in local warehouse for order fulfillment.

Step 7: Post-sales Optimization and Supplier Relationship Management

7.1 Analyze Post-sales Data and Optimize Products

Track return rates, negative reviews, and complaints. Identify causes (production, transport, design). For supplier-related issues, communicate improvements. Adjust specifications for design defects and upgrade products with suppliers.

7.2 Maintain Long-term Cooperative Supplier Relationships

- Pay balance on time to maintain good credit.

- Maintain regular communication, share market trends and sales data.

- Provide incentives for high-quality suppliers: increase purchase volume, extend cooperation, recommend to other sellers.

- Handle disputes calmly, prioritize negotiation and mediation, and maintain 1-2 alternative suppliers to prevent supply chain disruption.

7.3 Continuously Optimize the Sourcing Process

Summarize each sourcing cycle: evaluate supplier screening, sample testing, and logistics costs. Optimize evaluation systems, quality inspection standards, and logistics strategies. Gradually establish a standardized sourcing system to improve efficiency and reduce risks.

Conlusion

Long-term competitiveness in the Magic Water Elf Kit market depends on regulatory compliance, material safety, and controlled production consistency.

Suppliers with certification readiness, structured quality control, and scalable manufacturing are better positioned to meet evolving safety standards and diversified consumer demand.