When developing a private-label or branded Magic Water Elf Kit, customizing molds and packaging is one of the most effective ways to differentiate your product in the market.

In general, it is possible to customize both molds and packaging with qualified suppliers, especially those offering OEM and ODM services.

However, this process involves technical capability, cost control, compliance requirements, and cooperation management.

Therefore, customization should be approached strategically rather than casually.

What Customization Is Typically Available?

Customization isn’t just a nice-to-have—it’s a strategic way to make your products stand out in a crowded market. From the shape of the product itself to the packaging and branding, every detail can be tailored to your business needs. Let’s explore the main customization options that suppliers typically offer.

Custom Mold Shapes and Themes

Before diving into packaging or branding, the most noticeable aspect of a product is often its shape and design. Custom molds allow your products to leave a lasting impression on customers, making them more memorable and shareable.

Manufacturers typically offer a wide range of options: from characters and animals that appeal to children or niche markets, to seasonal designs like Christmas, Halloween, or promotional event-themed shapes. Custom molds allow your product to stand out on the shelf, attract attention online, and connect with your target audience.

Example: A chocolate manufacturer working with a toy company might create chocolate molds shaped like popular cartoon characters. This not only increases appeal but also opens opportunities for limited-edition campaigns, boosting both sales and brand visibility.

Common Misconception: Many buyers assume custom molds are prohibitively expensive. In reality, most suppliers can produce molds at reasonable costs, especially when ordered in medium or large quantities. The key is early planning and clear design specifications.

With the product shape finalized, the next step is ensuring it’s presented to customers in a way that reinforces your brand. That’s where packaging comes into play.

Packaging Options for Branding and Retail Display

Packaging is more than just a wrapper—it’s a critical component of your branding strategy. Well-designed packaging not only protects the product but also communicates your brand story and convinces customers to make a purchase.

Suppliers usually provide custom packaging solutions, including printed boxes, bags, blister packs, and even eco-friendly materials. Packaging can be tailored to:

- Highlight your brand colors and logo

- Optimize for retail display, such as shelves, counters, or online presentation

- Include product information, QR codes, or marketing messages

Example: A premium snack company customized clear window boxes with vibrant graphics and product descriptions. This not only made the product visually appealing but also increased customer trust and perceived value, leading to higher conversion rates both in-store and online.

Tip: Always request mock-ups before final production. This ensures the packaging aligns with your marketing strategy and avoids costly redesigns later.

Once the packaging is thoughtfully designed, the final step is to integrate your own branding through logos or private-label options—this is what truly makes a product yours.

Logo Printing and Private-Label Opportunities

Adding a logo or opting for private-label products allows your brand to take center stage. This customization ensures that your product is not just another generic item but a unique offering associated directly with your company.

Most manufacturers support various methods such as embossing, engraving, silk-screen printing, or heat transfer, depending on the product material and size.

Benefits include:

- Building brand recognition without investing in manufacturing infrastructure

- Offering products exclusive to your store or online platform

- Simplifying inventory management, as the supplier handles production and basic compliance

Example: A startup selling health supplements partnered with a factory for private-label gummies. By printing their logo on the gummies and boxes, they launched a fully branded product line without owning a production facility. This approach saved time and capital while maintaining full control over branding.

Pitfall to Avoid: Ensure trademark and copyright compliance when printing logos or designs. Working with a reputable supplier who understands private-label rules prevents potential legal issues.

How Suppliers Present Customization Options?

Understanding how suppliers showcase their customization capabilities can save you time and help you make informed decisions when sourcing products.

Not all suppliers offer the same level of flexibility, and knowing the difference between their service models and examples of past work will guide you toward the best fit for your business.

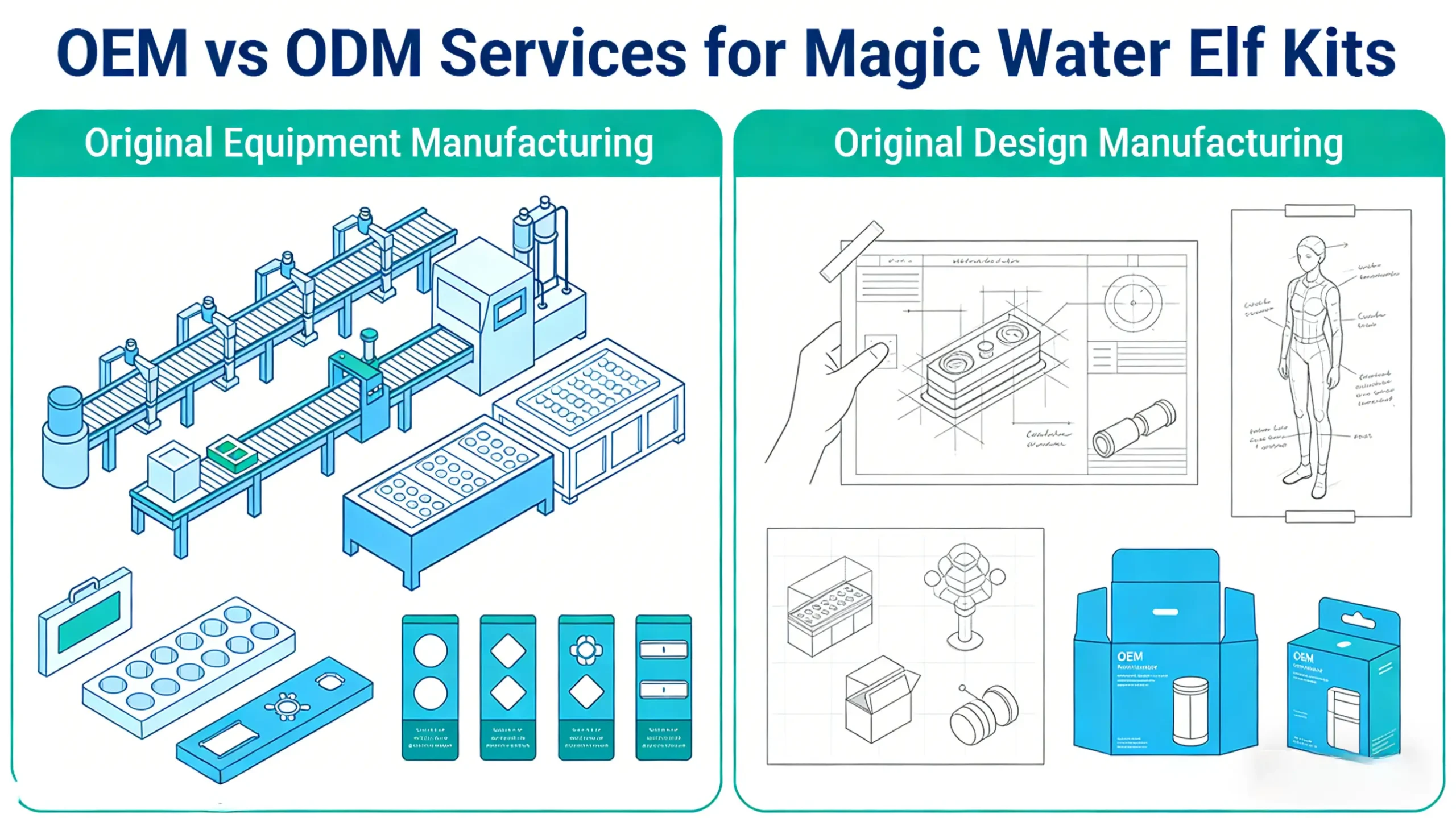

OEM vs ODM Services for Magic Water Elf Kits

Before exploring actual examples, it’s important to understand the two main service models suppliers offer: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer).

OEM allows you to provide your own designs or specifications, while the supplier produces the product exactly according to your requirements. This is ideal if you have a clear vision for your Magic Water Elf Kit.

ODM offers pre-designed products that can be customized slightly to suit your branding. This is convenient if you want a faster turnaround or inspiration for your product concept.

Example: A retailer wanting a unique holiday-themed Magic Water Elf Kit might choose OEM to create a custom snowflake design, while a small online seller could use ODM for seasonal kits with minor tweaks, like color or packaging.

Once you understand the service type, you can better evaluate which suppliers align with your needs and how they demonstrate their capabilities.

Examples of Suppliers Offering Customization

Suppliers often provide portfolios or case studies to illustrate their customization expertise. These examples show what’s possible in terms of mold design, packaging, and branding, helping you visualize the final product.

Example: Some Magic Water Elf Kit manufacturers display a gallery of past designs on their website, showing variations like themed characters, interactive elements, or seasonal packaging. By reviewing these examples, you can assess quality, creativity, and production capabilities before reaching out.

Tip: Look for suppliers who document the customization process—from design approval to final production—so you can anticipate timelines and potential challenges.

After seeing how suppliers demonstrate their work, the next logical step is to compare standard kits with fully customized versions to understand the value customization adds.

Sample Showcase: Standard vs Custom Kits

A direct comparison between standard kits and customized versions highlights the tangible benefits of personalization. Standard kits are usually ready-to-ship products with generic designs, while custom kits allow for unique mold shapes, packaging, and branding tailored to your target audience.

Example: A standard Magic Water Elf Kit might feature generic elf designs and plain packaging, whereas a customized version could have personalized elf characters, festive colors, and a branded box with your logo. This difference can significantly impact perceived value and sales potential, especially in competitive markets.

Pitfall to Avoid: Some buyers focus only on cost and overlook the impact of customization on brand recognition and customer engagement. The added investment in customization often translates into higher conversion rates and stronger brand loyalty.

Customization Costs and Minimum Order Requirements

After understanding what customization is available and how suppliers present their options, the next critical factor is costs and order requirements.

Customization adds value, but it also involves additional expenses and production considerations.

Knowing these details early helps you plan your budget and choose the right supplier.

Typical Tooling Fees for Custom Molds

Before production begins, most suppliers charge a tooling fee to create custom molds. This fee covers the design, engineering, and manufacturing of molds specific to your product.

Example: A Magic Water Elf Kit manufacturer might charge $150–$500 per mold depending on complexity, size, and material. While this may seem like an extra cost, it’s a one-time investment: once the mold is created, it can be used for repeated production runs, reducing per-unit costs in the long term.

Tip: Discuss mold reuse and modifications with suppliers. Some allow minor adjustments for free, while others may charge additional fees. This can influence both cost efficiency and flexibility.

Minimum Order Quantities (MOQ) for Custom Kits

Suppliers often set a MOQ to ensure production efficiency and cost-effectiveness. This varies depending on product type, complexity, and customization level.

Example: For Magic Water Elf Kits, standard molds may have MOQs as low as 100–200 units, while fully custom molds could require 500–1,000 units per design. MOQs are particularly relevant for small businesses or startups, as they affect initial investment and inventory management.

Common Misconception: Many buyers assume MOQs are rigid. In reality, negotiation is possible, especially if you’re combining multiple designs or committing to recurring orders.

Bulk Pricing Examples and Cost Range

The per-unit cost decreases as order volume increases, making bulk orders more economical. Suppliers often provide tiered pricing to incentivize larger purchases.

Example: A standard Magic Water Elf Kit may cost $3.50 per unit for 200 units, while the same kit could drop to $2.80 per unit at 1,000 units. Custom kits with unique molds and packaging might start at $5–$6 per unit for small batches but can decrease significantly in larger volumes.

Tip: When planning your order, always calculate total cost including tooling, packaging, and shipping, not just the unit price. This ensures you understand the real investment and projected profit margin.

Pitfall to Avoid: Focusing solely on unit price can lead to underestimated costs. Factor in customization fees, MOQ constraints, and logistics to avoid surprises.

Safety and Compliance Considerations

After evaluating customization options, supplier capabilities, and costs, the next crucial factor is safety and regulatory compliance.

Even the most creative or well-branded Magic Water Elf Kit will fail in the market if it doesn’t meet toy safety standards.

Ensuring compliance protects both your customers and your brand reputation.

ASTM F963 and EN71 Toy Safety Standards

The first step in assessing safety is understanding the key regulatory standards for toys. In the U.S., ASTM F963 is the standard for toy safety, covering mechanical, physical, and chemical properties. In Europe, EN71 serves a similar purpose, ensuring that toys sold in the EU are safe for children.

Example: A Magic Water Elf Kit sold in the U.S. must pass ASTM F963 testing for small parts, sharp edges, and chemical safety, while kits exported to Europe require EN71 compliance for heavy metals and migration limits. Suppliers who proactively follow these standards demonstrate professionalism and reduce your risk of product recalls.

Tip: Always request compliance documentation before placing an order to confirm the product meets target market requirements.

Material Safety and Non-Toxic Requirements

Beyond standards, the materials used in your kits must be non-toxic and suitable for children. This includes plastics, paints, coatings, and adhesives. Using safe, certified materials not only protects users but also enhances your brand’s credibility.

Example: Some Magic Water Elf Kit manufacturers use food-grade plastics and water-based paints to ensure all components are non-toxic and safe for children. Highlighting this in marketing materials can also increase customer confidence.

Common Misconception: Buyers often assume that passing safety standards alone guarantees material safety. In reality, ongoing quality control is necessary to ensure every batch remains compliant.

How to Verify Supplier Certifications?

Not all suppliers who claim compliance can provide valid certification. Verification is essential to avoid legal issues and protect your brand.

Steps to verify:

- Request copies of official certificates (ASTM, EN71, ISO, etc.)

- Check certificate validity dates and issuing organizations

- If possible, cross-verify through third-party testing labs or online registries

Example: A supplier may provide an EN71 certificate, but upon verification, the certificate is expired or issued by an unrecognized lab. Verifying ensures that the kits you import are truly compliant.

Tip: Always maintain documentation for regulatory audits and customs clearance, as non-compliant products can be blocked or recalled.

Sample Approval and Production Timeline

After confirming customization options, costs, and safety compliance, the next critical stage is sample approval and production planning.

This step ensures that the final product matches your expectations, avoids costly mistakes, and helps maintain a smooth workflow from design to delivery.

Understanding how to request samples, estimating lead times, and preventing delays are all key to a successful production process.

How to Request Pre-Production Samples?

Before committing to full-scale production, requesting a pre-production sample is essential. Samples allow you to inspect quality, evaluate materials, and verify design details such as mold shapes, packaging, and branding.

Example: When ordering a Magic Water Elf Kit, you might request one sample of the custom mold and packaging combo to confirm that colors, dimensions, and logos match your specifications. This step can save time and money by catching potential issues early.

Tip: Provide detailed specifications, reference images, and color codes when requesting samples. Clear communication helps suppliers produce samples that truly reflect the final product.

Estimated Lead Time for Custom Mold Production

Understanding the lead time helps you plan inventory and launch schedules. Lead times vary depending on mold complexity, order size, and supplier capacity.

Example: For Magic Water Elf Kits, a simple mold may take 7–10 days to produce, while a highly detailed custom mold could take 2–3 weeks. Lead times for mass production follow after mold approval, typically ranging from 3–6 weeks depending on order volume and packaging complexity.

Tip: Always confirm lead times in writing and include them in your production schedule. This reduces the risk of unexpected delays and ensures timely delivery.

Tips to Avoid Production Delays

Production delays are a common challenge when working with custom products. Proactive communication and planning can help mitigate most issues.

Tips include:

- Approving samples promptly and providing feedback clearly

- Confirming all specifications and packaging requirements before production starts

- Maintaining regular communication with the supplier during the production process

- Planning for logistics and shipping contingencies to accommodate any unexpected delays

Example: A supplier might notify you of a material shortage. If you have approved all specifications and maintain regular check-ins, the issue can be resolved quickly without impacting the overall timeline.

Pitfall to Avoid: Waiting until full production starts to identify design or material issues. Early sampling and clear approvals are essential for avoiding costly errors and delays.

Materials and Design Considerations

After planning customization, understanding supplier options, managing costs, ensuring safety, and scheduling production, the next step is to carefully select materials and design elements.

The choice of materials directly impacts product durability, safety, usability, and overall customer satisfaction, while thoughtful design enhances appeal and brand perception.

Recommended Mold Materials for Durability and Easy Demolding

A durable mold ensures consistent quality and reduces production issues. Selecting the right mold material can also make demolding easier, reducing breakage and maintaining product integrity.

Example: For Magic Water Elf Kits, manufacturers often use food-grade silicone or high-quality ABS plastics for molds. These materials withstand repeated use, provide sharp detail, and allow easy removal of delicate shapes like elf figurines or intricate designs.

Tip: Discuss expected production volume with your supplier when choosing mold material. Some materials are better for small batches, while others excel in mass production.

Packaging Materials and Design Tips

Packaging not only protects the product but also communicates your brand story. Selecting the right materials and design elements ensures your product is safe, attractive, and market-ready.

Example: Suppliers often recommend eco-friendly cardboard, PET windows, or reusable boxes for Magic Water Elf Kits. Incorporating clear panels, vibrant graphics, and secure inserts can enhance presentation while preventing product damage.

Tip: Align packaging materials with brand positioning and target audience expectations. Premium designs often justify a higher price point, while simple packaging may suit budget-conscious markets.

Water and Color-Safe Materials for Magic Kits

Because these kits involve water, dyes, or other interactive components, it is critical to select materials that are non-toxic, water-resistant, and color-safe. This ensures safe play and prevents staining or product degradation.

Example: High-quality Magic Water Elf Kits use food-grade, water-safe plastics for figurines, and non-toxic dyes for water effects. This ensures children can safely interact with the product without any risk of harmful exposure or unexpected mess.

Tip: Verify that all components, including paints, plastics, and coatings, comply with ASTM F963, EN71, or other relevant safety standards. Highlighting this in your marketing materials can increase trust and perceived value.

Jaredrise – Supplier Capabilities for Magic Water Elf Kit

After reviewing general customization, cost, safety, production, and materials considerations, it’s helpful to look at a real supplier example.

Jaredrise demonstrates how a capable manufacturer can bring your Magic Water Elf Kit from concept to finished product while ensuring quality and compliance.

Understanding their capabilities and best practices can guide your supplier selection process.

Production Capabilities

Jaredrise has the ability to produce custom molds and packaging according to client specifications, whether it’s unique elf shapes, themed kits, or specialized packaging for retail or gifting purposes. Their production capabilities include:

- Custom mold creation for detailed figurines and interactive elements

- Flexible packaging solutions, including branded boxes, windowed displays, and eco-friendly materials

- Support for OEM and ODM orders to suit different levels of design involvement

Tip: Work closely with the supplier to communicate design specifications, color codes, and intended usage, ensuring that the final product meets your vision.

Key Considerations When Working with Jaredrise

To get the most from your partnership with Jaredrise, focus on these areas before placing an order:

- Tooling ownership: Clarify whether molds belong to you or the supplier, which affects reorders and future modifications

- Minimum order quantities (MOQ): Understand the MOQ for custom molds and kits to plan budgets and inventory

- Material requirements and safety compliance: Confirm that all components meet ASTM F963, EN71, and non-toxic standards

- Sample review: Always request and review pre-production samples to ensure design accuracy, material quality, and overall functionality

Example: A client ordering a seasonal Magic Water Elf Kit may approve a pre-production sample to check the figurine details, packaging fit, and water/dye safety. Once approved, Jaredrise can move to mass production efficiently, reducing delays and ensuring consistency.

Tip: Maintain clear communication and documentation throughout the process to prevent misunderstandings and production errors.

Conclusion

In summary, customizing molds and packaging for Magic Water Elf Kits is feasible and widely practiced, but it requires systematic planning.

Mold customization involves higher investment and longer cycles, while packaging customization is more flexible and suitable for early branding.

Safety compliance remains the most critical risk factor throughout the process.