Many importers and Amazon sellers experience CPSIA or EN71 test failures after sourcing low-cost Magic Water Elf kits, leading to shipment delays, recalls, and account risk.

Industry audits from 2023–2024 show initial failure rates of 15–25%, primarily caused by non-certified resins, unsafe pigments, poor batch traceability, and inadequate heavy metal control under ASTM F963 and EN71-3.

Qualified manufacturers reduce these risks through systematic material control, including phthalate-free and BPA-free polymers, EN71-3:2019–compliant pigments, and documented COA and MSDS verification for every batch.

Experienced suppliers also support third-party testing by SGS, TÜV, or Intertek and maintain traceable batch coding systems.

Selecting a Magic Water Elf kit manufacturer with verified non-toxic materials shifts safety from post-production correction to source-level prevention, improving compliance reliability, platform stability, and long-term cost control.

Importing Magic Water Elf Kits That Fail Safety Testing

Many importers and Amazon sellers source Magic Water Elf kits based on low-cost samples, only to face CPSIA (U.S. Consumer Product Safety Improvement Act) or EN71 (EU Toy Safety Standards) test failures after mass production.

This leads to shipping delays, mandatory recalls, and significant financial losses.

Why Do Magic Water Elf Kits Often Fail CPSIA/EN71 Tests?

-

Use of Non-Certified Resins or Pigments: These toys expand in water. If the core materials—resins and pigments—are cheap, non-specialized grades, they are highly likely to contain or release harmful plasticizers like phthalates, which is the primary cause of test failure.

-

Lack of Batch-Level Material Traceability: Opaque supply chains mean manufacturers cannot provide the origin or safety certification for the specific resin and pigment batches used, making the risk uncontrollable.

-

Failure to Control Heavy Metals (ASTM F963 / EN71-3): Toys, especially components that children might put in their mouths, must strictly limit the migration of heavy metals such as lead and cadmium. Low-cost production often overlooks this critical requirement.

-

Typical Failure Rate Data: Industry audit reports (2023-2024) indicate that the failure rate for Magic Water Elf kits from low-cost suppliers is as high as 15%-25% in initial test batches, highlighting a widespread quality risk.

When selecting a supplier, it is vital to confirm they use non-toxic Magic Water Elf kit materials.

Seek out manufacturers capable of providing CPSIA-compliant Magic Water Elf kits or those who specialize as an EN71-compliant water toy manufacturer to eliminate risks at the source.

How Qualified Manufacturers Prevent These Test Failures?

A professional EN71-compliant water toy manufacturer ensures product safety through systematic controls:

-

Source Material Control: They strictly utilize non-toxic, phthalate-free, and BPA-free polymer materials as the base resin, eliminating hazardous chemicals from the very beginning.

-

Pigment Compliance Assurance: All pigments meet the stringent heavy metal migration limits set by the latest standards, such as EN71-3:2019. This ensures that no harmful metals leach out even after prolonged contact with water or saliva.

-

Documented Verification Process: Before production begins, the manufacturer requires and verifies the Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS) for every batch of raw materials, maintaining a complete material traceability system.

-

Authoritative Third-Party Testing: Prior to shipment, they proactively support or arrange for full-scale testing by internationally recognized labs like SGS, TÜV, or Intertek. Providing a passing report is the most reliable way to ensure every batch of Magic Water Elf kits is CPSIA compliant, guaranteeing smooth customs clearance and a safe market launch.

By choosing a partner with these qualifications, importers and sellers can significantly reduce the risk of recalls and delays while building long-term market credibility by offering safe, high-quality products.

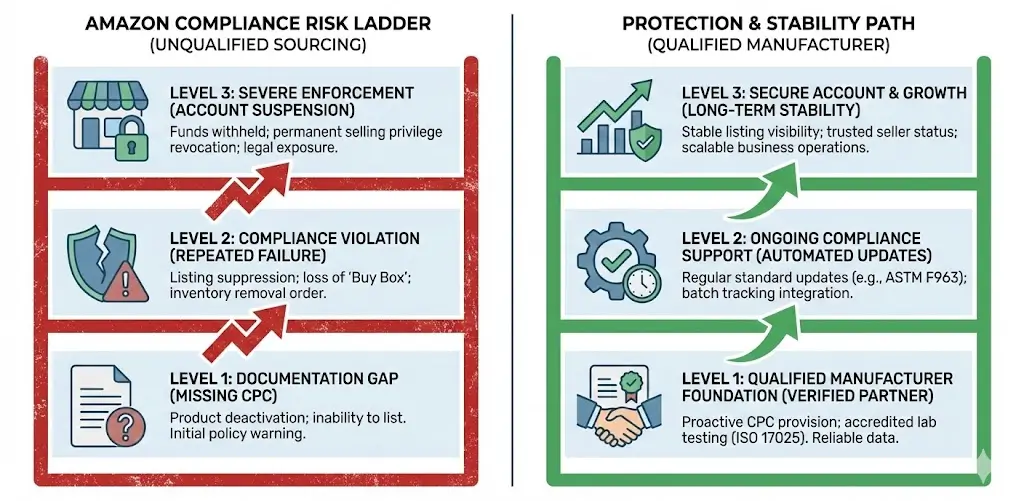

Selling Children’s Toys on Amazon or Retail Channels

On mainstream e-commerce platforms like Amazon (US/EU stations) and in offline retail channels, the compliance threshold for children’s toys is steadily rising. Platforms now mandate that sellers provide verifiable product safety documentation.

For children’s water toys like the Magic Water Elf kits, audits are particularly rigorous. A lack of compliance certification will lead directly to listing removals or total sales disruption.

Platform Risks Associated with Undisclosed Material Declarations

-

Amazon Safety Audits and CPC Requirements: Amazon regularly conducts safety audits, randomly requiring sellers to provide a Children’s Product Certificate (CPC) for their products. This certificate must be based on test reports from CPSC-accepted laboratories and clearly list all applicable safety rules (such as CPSIA and ASTM F963). Failure to submit this immediately will result in an instant listing takedown.

-

Delisting Due to Missing “Non-Toxic” Claims: If product descriptions or backend information fail to explicitly declare the use of non-toxic and hazard-free materials, the platform may flag the listing for incomplete information or potential risk, triggering an audit and sales suspension.

-

Chain Reaction Crises from Customer Complaints: Issues caused by inferior materials—such as strong odors, skin allergies, or color staining—will trigger negative reviews, returns, and safety complaints. Such complaints quickly alert the platform, leading to mandatory investigations and, in severe cases, the suspension of the seller’s entire account.

Consequently, partnering with an experienced Amazon-specialized Magic Water Elf kit manufacturer is critical.

They understand platform rules deeply, ensuring the product completes all compliance steps as a CPC-compliant Magic Water Elf kit. By sourcing from a reliable non-toxic water toy supplier, you eliminate the root cause of customer complaints.

How Manufacturer Core Competencies Mitigate Your Platform Risk?

A qualified manufacturer capable of protecting your business should possess the following verifiable qualifications:

-

Direct Experience with Amazon CPC Documentation: The factory should not only be familiar with testing standards but also deeply understand Amazon’s specific document templates and submission requirements (especially the 2024 updates). They can quickly generate CPCs and test reports that meet platform specifications, ensuring your documents “pass on the first try.

-

Verifiable Export Track Record: A history of consistent exports to high-standard markets like the US, EU, UK, and Canada is essential. This is not just proof of production capacity, but evidence that their products have withstood rigorous customs and market surveillance, significantly improving your shipping pace and security.

-

Time-Tested Stable Formulas: The core product formula should have been in stable production and market-tested for at least 3 years. This indicates that the material supply chain, production processes, and chemical safety are highly mature. Minimal batch-to-batch variation ensures that products purchased at different times maintain consistent safety and quality performance, which is the key to avoiding unpredictable compliance risks.

By choosing a manufacturer with these capabilities, you gain more than just a supplier—you gain a compliance partner who helps you mitigate platform risks, safeguard your sales channels, and maintain your brand reputation.

OEM and Private Label Buyers Requiring Verified Non-Toxic Materials

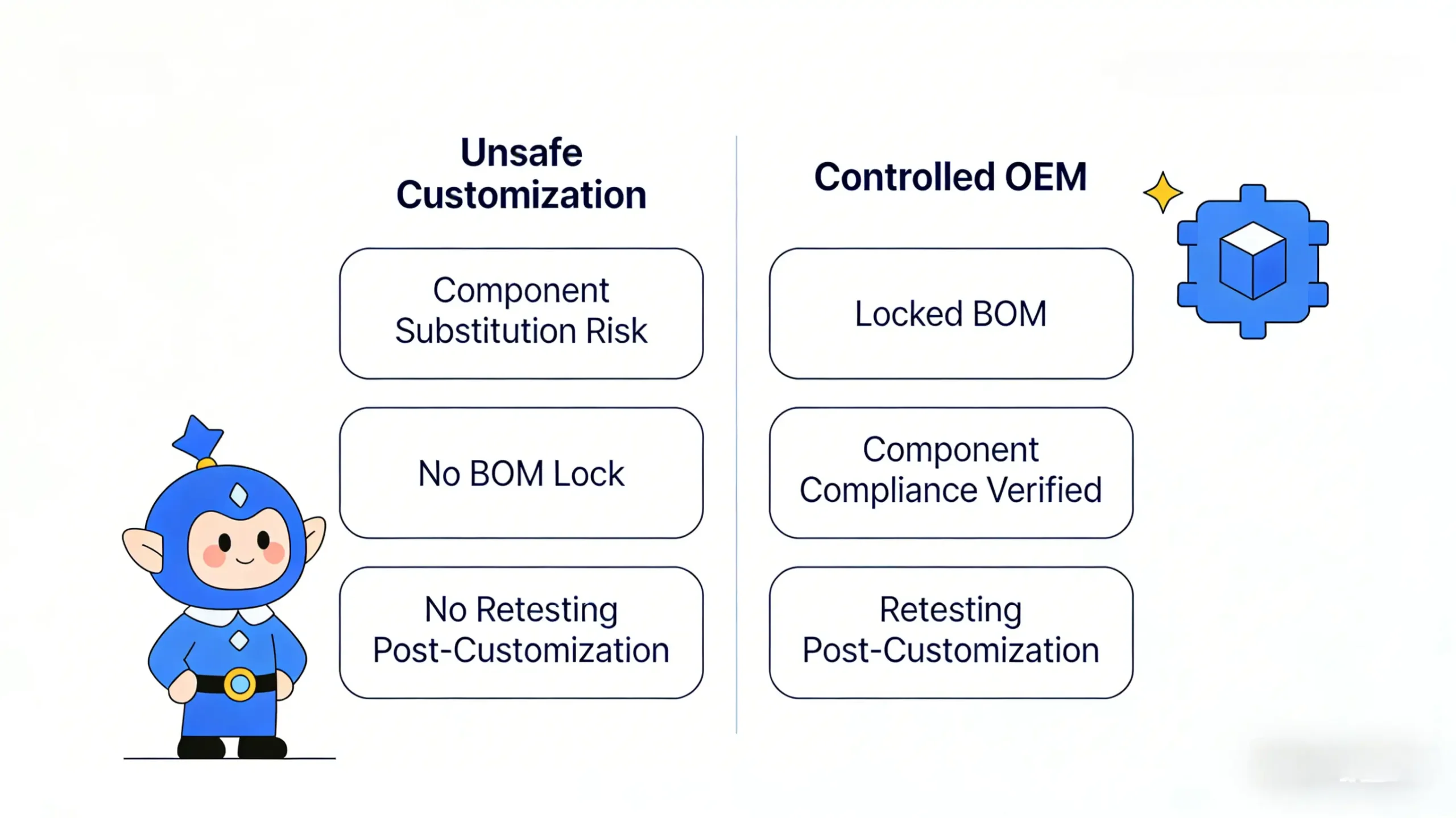

Distributors and brand owners often face a fundamental conflict when undertaking OEM manufacturing or private label customization for Magic Water Elf kits.

On one hand, they seek unique packaging and custom colors to establish brand identity; on the other, any minor material change during the production process can introduce unknown compliance risks, potentially rendering the entire batch non-compliant with the safety standards of the target market.

Common OEM Errors and Compliance Risks

When choosing an unproven OEM Magic Water Elf kit manufacturer, the following common mistakes can significantly increase your compliance risks and financial exposure:

-

Changing Pigments for Branding Without Re-testing: To achieve a unique brand aesthetic, sellers often request specific color adjustments. However, if the new pigments have not undergone critical safety tests—such as EN71-3 heavy metal migration—the entire batch may fail to meet regulatory requirements.

-

Using Outsourced Fillers with Mismatched MSDS: To cut costs, some manufacturers use third-party fillers (such as shredded paper or foam beads) inside the packaging. If the Material Safety Data Sheets (MSDS) for these materials are not verified, they may contain hazardous substances that contaminate the product.

-

Formula Adjustments Without Re-certification: Any minor tweak to the formula regarding expansion rate, texture, or appearance is legally considered a “new product.” Without mandatory re-testing and certification, the original CPC (Children’s Product Certificate) becomes invalid, leaving the product in a legally “uncertified” state.

To secure a safe and reliable private label non-toxic water elf kit, it is essential to partner with a customized magic water elf toy factory that maintains a rigorous compliance management system.

How Experienced Manufacturers Control OEM Safety Risks?

A professional manufacturer uses institutionalized processes to ensure your customized magic water elf toys meet personalized branding needs while remaining 100% safe:

-

Locked Bill of Materials (BOM): Once the initial sample is approved, the factory creates a “locked” Bill of Materials for your OEM order. This explicitly defines the brand, model, and safety certificate numbers for all resins, pigments, and packaging fillers. Any change must go through a formal application and approval process to prevent unauthorized material substitution.

-

Strict “Change-Means-Retest” Policy: Any adjustment to color or formula, or even a change in a sub-tier supplier, triggers a mandatory re-testing process. The factory will clearly communicate the risks and costs involved and issue a complete third-party test report based on the new sample, ensuring your private label non-toxic water elf kit always holds valid compliance documentation.

-

Internal Compliance Reviews Aligned with U.S. Regulations: Qualified factories establish dedicated internal compliance teams whose standards are strictly aligned with core regulations like CPSIA 16 CFR Part 1307 (prohibition of certain phthalates in children’s toys). Audits are conducted at every critical stage—material intake, pilot production, and pre-mass production—to ensure the entire OEM process operates within a safety framework.

By partnering with such a manufacturer, you gain more than just production capacity; you gain an auditable, traceable, and legally protected safety production system. This allows you the freedom to customize your brand with absolute confidence in your product’s compliance.

How to Evaluate a Magic Water Elf Kit Manufacturer Using Non-Toxic Materials?

(This checklist is highly structured for systematic auditing by procurement teams. Its key points are also optimized for search engine snippets.)

To help you efficiently and accurately vet high-quality suppliers and avoid the risks mentioned in previous scenarios, we have developed the following core evaluation checklist. A comprehensive verification of both the factory and its materials is the most critical step in securing a safe Magic Water Elf kit supplier.

Factory and Material Verification Checklist

When engaging with potential suppliers, be sure to request written proof for each item on this list and cross-verify the data. A truly reliable certified water toy manufacturer should be able to provide these items without hesitation.

1. Explicit Phthalate-Free / BPA-Free Material Declarations

-

Documents to Verify: Request a written statement from the supplier for the final product (specifically the expansion materials), confirming they do not contain phthalates or Bisphenol A (BPA) prohibited by CPSIA and REACH regulations.

-

Importance: This is a legal entry requirement for major global children’s product markets and the cornerstone of product safety.

2. MSDS (Material Safety Data Sheets) & COA (Certificate of Analysis) for All Raw Materials

-

Documents to Verify: Check the MSDS (to understand chemical composition and hazards) and COA (to prove compliance with specific safety standards) for all raw materials, including resins, pigments, and packaging fillers.

-

Importance: This is the foundation of material traceability, proving the factory controls quality at the source rather than relying on “post-production” corrective testing.

3. Valid EN71-3 / ASTM F963 Test Reports (Within the Last 12 Months)

-

Documents to Verify: Request recent test reports issued by authoritative third-party laboratories such as SGS, TÜV, or Intertek. The more recent the report, the better, ensuring it complies with the latest versions of the standards.

-

Importance: This proves the factory’s current production formulas consistently meet the core physical, mechanical, and heavy metal migration requirements of the EU (EN71) and the US (ASTM F963).

4. Proven Compliance Experience with the Latest Post-2023 CPSIA Standards

-

Documents to Verify: Ask for a sample CPC (Children’s Product Certificate) for products recently exported to the US (2023 or later). Confirm that the referenced testing rules are updated to the latest versions (e.g., ASTM F963-23).

-

Importance: US regulations are updated frequently. Experience proves the factory proactively tracks regulatory changes rather than sticking to outdated standards, ensuring your products face no obstacles in the US market.

5. Traceable Batch Coding System

-

Verification Method: Check if the product packaging or smallest sales unit features a production batch number (Lot Code). Ask if this code can trace back to the specific production date, production line, and even the raw material batches used.

-

Importance: In the event of a market inspection or customer complaint, a traceability system allows for rapid identification of the problem scope and precise recalls, protecting your brand reputation and minimizing losses.

Core Value Summary

By systematically completing these five verification steps, you will find more than just a supplier—you will find a verified non-toxic Magic Water Elf kit factory. They will provide you with:

-

Compliance Certainty: Guaranteeing smooth entry into your target markets.

-

Risk Controllability: Significantly reducing the risk of recalls, delistings, and legal claims.

-

Brand Protection: Providing a solid foundation of compliant, safe products to maintain long-term brand credibility.

We recommend using this checklist during three critical stages: initial supplier screening, on-site factory audits, and immediately before placing an order to ensure safety and transparency throughout the partnership.

Why “Non-Toxic Materials” Are a Strategic Long-Term Cost Control, Not Just a Compliance Requirement?

Viewing “non-toxic materials” solely as a compliance expense to be checked off is a common business misconception. For savvy enterprises, it is actually a core long-term cost control and risk management strategy.

Investing in a verified non-toxic material supply chain may result in a slightly higher initial unit price, but it proactively mitigates massive hidden costs and brand-killing disasters that can threaten a company’s survival.

The Quantifiable Business Impact

Choosing cheap but unreliable material suppliers creates financial and brand risks that far outweigh any temporary savings. The following data highlights the real stakes involved:

-

Exorbitant Direct Costs of Safety Recalls: In the U.S. market, the average direct cost of a single safety recall for children’s toys—including logistics, disposal, customer compensation, platform fines, and legal fees—typically ranges from $120,000 to $300,000. A single recall event is often enough to wipe out the total profits of dozens of high-margin orders.

-

Long and Costly Brand Recovery Cycles: If a product safety issue leads to consumer complaints or negative media coverage, brand reputation suffers a devastating blow. Market research indicates that it takes 12 to 18 months to rebuild consumer trust. During this period, marketing expenses surge while conversion rates plummet, creating an invisible but massive “brand tax.”

-

Significant Testing Cost Savings via Stability: A long-term partnership with a reliable non-toxic Magic Water Elf kit material supplier who maintains stable formulas and standardized processes ensures product consistency. This stability eliminates the need for repetitive, redundant testing caused by material fluctuations. Over time, this consistency can save you 30%–40% annually on third-party testing and certification fees.

Conclusion and Strategic Recommendation

Positioning “non-toxic materials” at the core of your strategy is essentially purchasing “business continuity insurance.” It doesn’t just prevent sudden, catastrophic financial losses; it strategically safeguards your brand equity—your most valuable intangible asset—and lowers long-term operational costs through supply chain optimization.

Smart decision-makers should look beyond the “cost of compliance” and instead evaluate the long-term ROI of material safety. Selecting and securing a partner with an excellent reputation for material safety is the bedrock of sustainable profitability and brand growth.

Conclusion

Children’s water toys face increasing regulatory scrutiny in the US and EU, particularly on platforms like Amazon that require CPC documentation and up-to-date safety reports.

Magic Water Elf kits frequently fail compliance checks when manufacturers use uncertified resins, untested pigments, or lack batch-level material traceability.

These issues commonly trigger EN71-3 or CPSIA violations related to phthalates and heavy metal migration.

Experienced manufacturers prevent such failures by locking material formulas, enforcing “change-means-retest” policies, and maintaining compliance systems aligned with CPSIA 16 CFR Part 1307 and ASTM F963-23.

Stable formulas tested over multiple years reduce repeat testing costs by 30–40% and lower recall exposure, which can exceed USD 120,000 per incident.

Choosing a non-toxic Magic Water Elf kit manufacturer is therefore a strategic risk-management decision, not a cosmetic compliance step.