This report summarizes leading manufacturers and brands of CPSIA-compliant Water Elf Kits for the U.S. market, highlighting Ningbo Jaredrise, XinXiang Alpha, Nicella, and Early Light Industrial as core suppliers.

All adhere to federal safety standards for children’s craft toys, covering chemical limits, small part safety, and mandatory certifications including CPC, ASTM F963-23, and LHAMA/TRA.

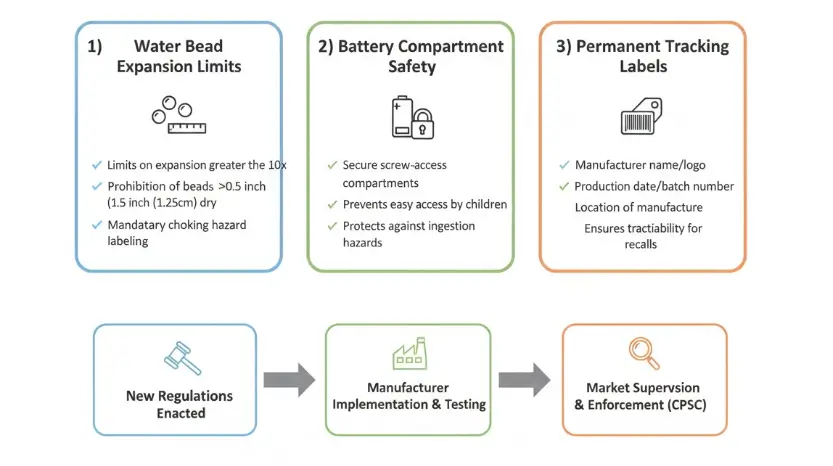

Key production capabilities include large-scale OEM/ODM execution, gel formulation stability, and packaging standardization. Recent regulatory updates emphasize water bead expansion limits, secured battery compartments, and permanent tracking labels to mitigate ingestion or chemical risks.

Manufacturers demonstrate compliance through third-party testing, batch-specific CPC issuance, and documentation retention for customs verification. Buyers are advised to verify lab IDs, ensure ASTM F963-23 testing, and perform independent physical sample checks to validate chemical and mechanical safety.

These measures ensure legal market entry, reliable supply, and reduced safety risk while supporting private label development and differentiated product offerings.

Top Manufacturers and Brands for CPSIA-Compliant Water Elf Kits

To facilitate market entry into the United States, this report identifies core manufacturers and retail brands of Water Elf Kits that comply with U.S. federal safety regulations (CPSIA).

It provides a reference for procurement, OEM/ODM cooperation, and private label development.

As a craft toy for children, Water Elf Kits must strictly adhere to CPSIA and supporting standards in terms of gel materials and accessory safety to be legally sold in the U.S. market.

These manufacturers boast mature compliant production systems, large-scale production capacity, and international certification qualifications. They can meet customers’ OEM/ODM customization needs and serve as key partners for brands seeking to quickly enter the U.S. market.

Ningbo Jaredrise Import & Export Co., Ltd.

Ningbo Jaredrise is a manufacturing-oriented supplier with a strong focus on OEM/ODM execution for gel-based toys and related children’s novelty products.

Its core strength lies in standardized production management, cost control, and export-oriented compliance coordination, making it suitable for buyers seeking stable mid-to-large volume supply without excessive customization complexity.

In terms of compliance, Jaredrise has practical experience aligning products with CPSIA requirements for the U.S. market, including coordination of third-party testing for lead content, phthalates, and mechanical safety of small parts.

While it does not position itself as a technology-driven gel R&D specialist, it operates within established, market-validated material formulations, which helps reduce compliance risk and testing uncertainty for repeat SKUs.

From a production perspective, the company emphasizes batch consistency, packaging standardization, and delivery reliability.

Its OEM model is particularly well-suited for Amazon sellers, importers, and distributors who prioritize predictable quality, competitive pricing, and smooth customs clearance over frequent formula changes.

Jaredrise can support private label projects, basic mold variations, and packaging localization, allowing buyers to differentiate at the branding level while keeping manufacturing risks under control.

Overall, Ningbo Jaredrise fits well as a pragmatic supply partner for Water Elf–type products where compliance stability, cost efficiency, and execution reliability are the primary decision factors, especially for buyers scaling proven products rather than experimenting with new material systems.

XinXiang Alpha Manufacturing Ltd. (Alpha Science Toys)

As a leading manufacturer in the STEM toy sector, Alpha has over 14 years of industry experience, with significant advantages in safety control and large-scale production of children’s science toys.

Its core compliance capability lies in strict adherence to CPSIA standards—all Water Elf Kits undergo testing by CPSC-accepted third-party laboratories such as SGS and Intertek, covering critical items including lead content, phthalate limits, and small part safety.

In addition to CPSIA, its products also comply with international toy safety standards such as ASTM F963 and EN 71, and hold multiple system certifications including ICT, ISO 9001, and GSV, making them compatible with the supply chain standards of international retail giants like Walmart and Metro.

In terms of production capacity, Alpha specializes in large-scale OEM production, capable of undertaking bulk orders with stable delivery.

It can also optimize product formulas based on customer needs, using environmentally friendly gel materials that balance safety and playability.

It is an ideal partner for brands pursuing compliance and large-scale production.

Shenzhen Yidiantong E-commerce Co., Ltd. (Nicella)

A professional supplier of Water Elf and “Aqua Fairy” gel-based toys, Nicella’s core competitiveness lies in its in-depth research and optimization of Water Elf gel technology. It can precisely control the non-toxicity and stability of gel materials, eliminating the risk of chemical contamination from the source.

With existing export experience, Nicella has a mature understanding of U.S. market compliance requirements, and its Water Elf Kits are adapted to international logistics and customs clearance processes, enabling quick connection with U.S. importers.

As a category-focused supplier, Nicella offers targeted product customization services, including gel colors, mold styles, and accessory combinations.

It can also assist customers in completing CPSIA-related testing and CPC certificate processing, making it suitable for partners looking to deepen their presence in the Water Elf niche and pursue product differentiation.

Early Light Industrial Co., Ltd.

As one of the world’s largest contract toy manufacturers, Early Light Industrial has the core capability to provide high-volume, compliant products for top international brands. Its production system strictly follows CPSIA and U.S. retail safety standards, with a comprehensive quality control process.

From raw material procurement (e.g., gel substrates, plastic molds) to finished product delivery, it conducts rigorous screening for harmful substances such as lead and phthalates.

Meanwhile, to prevent choking hazards for children, it strictly tests the size and assembly firmness of small parts.

Leveraging strong supply chain integration capabilities, the company can achieve large-scale mass production of Water Elf Kits and quickly adjust product specifications in response to market demand.

It is suitable for partners requiring bulk order delivery and seeking stable supply chains and international brand OEM experience.

Supplementary Notes on Core Compliance Requirements

U.S. market compliance control for Water Elf Kits is centered on the CPSIA, with core requirements including:

- Chemical limits: Lead content in surface coatings ≤90ppm, lead content in substrates ≤100ppm, and total content of 6 phthalates (including DEHP and DBP) ≤0.1%;

- Third-party certification: Test reports must be issued by CPSC-accepted laboratories, and CPC certificates must be issued by importers/manufacturers, containing 8 core elements such as product information, test standards, and laboratory qualifications;

- Physical safety: Small parts must pass the 31.75mm standard test cylinder to avoid choking hazards for children, with no sharp edges;

- Labeling requirements: Permanent traceability labels must be attached, including manufacturer information, production batches, and age warnings.

For OEM/ODM cooperation, priority can be given to Alpha Science Toys (comprehensive compliance and production capacity advantages), Nicella (professionalism in gel technology), and Early Light Industrial (international brand OEM experience).

For private label development, brands can reference the strategic models of Teexpert (e-commerce platform compliance), Kiditos (high-end offline channels), and Klever Kits (regular compliance audits).

Regardless of choosing OEM/ODM or private labeling, it is essential to ensure products pass complete CPSIA testing and obtain CPC certification, with compliance documents properly filed to meet customs and platform reviews and reduce market risks.

Mandatory Safety Certifications for the US Market

To ensure Magic Water Elf products can legally enter the US market and avoid compliance risks, manufacturers must provide three specific documents to be recognized as “CPSIA-compliant.”

As a children’s craft toy containing chemical components, Magic Water Elf products require safety certification covering overall compliance, physical-chemical safety, and contact safety.

All three documents are mandatory and form the core basis for manufacturers to make compliance decisions, pass customs, and sell the products.

The following are the three mandatory safety documents for Magic Water Elf products, along with detailed requirements:

Children’s Product Certificate (CPC)

The CPC is a mandatory compliance document for children’s products (for use by children aged 12 and under) in the US market.

It is not issued by third-party labs but is an official declaration issued by the manufacturer or importer based on product test results, with legal effect.

For Magic Water Elf products, the CPC must include the following key elements:

(1) detailed product information, including name, model, production batch, manufacturer/importer name, address, and contact information;

(2) compliance basis, clearly stating that the product meets CPSIA requirements and relevant standards (e.g., ASTM F963-23);

(3) testing information, including the name, qualification, and test date of the third-party lab that issued the test report;

(4) declaration of responsibility, confirming that the product has been tested and meets all applicable US children’s product safety standards and is safe for the market.

Note that the CPC must fully correspond to the test report and include all product components (e.g., gel, molds, tools), otherwise it will be deemed non-compliant.

ASTM F963-23 Test Report

ASTM F963-23 is the latest US toy safety standard, replacing previous versions, and is the core testing basis for Magic Water Elf products entering the US market.

The test report must be issued by a CPSC-recognized third-party laboratory, and all test items must show a “Pass” result to serve as valid support for the CPC. For Magic Water Elf products, the standard focuses on three main testing dimensions:

- Physical/Mechanical Testing: Primarily screens for choking hazards and structural safety. Small parts in the set (if any) must pass the 31.75mm test cylinder to prevent swallowing; molds and tools must have no sharp edges or points; gel containers must not be easily breakable or leak, preventing children from exposure to excessive chemicals.

- Flammability Testing: Tests non-textile components (e.g., plastic molds, paper instructions) for burn rate and flame resistance. Flammable materials are prohibited to avoid fire risks during use.

- Heavy Metal Limits: Tests for lead, mercury, cadmium, and other harmful heavy metals in gels, plastic components, and surface coatings. Limits must meet CPSIA and ASTM F963-23 requirements (e.g., surface coating lead ≤90 ppm, substrate lead ≤100 ppm), eliminating heavy metal ingestion risks.

LHAMA (ASTM D4236) / Toxicological Risk Assessment (TRA)

Since Magic Water Elf kits contain chemical components such as sodium alginate and calcium lactate, they are considered chemical-containing children’s toys and require LHAMA certification or a toxicological risk assessment (TRA) report.

These are issued by professional toxicologists to prove that the gel and chemical components are non-toxic, non-irritating, safe for skin contact, and pose no ingestion risk (including occasional accidental ingestion).

LHAMA (ASTM D4236) mainly applies to art materials.

If Magic Water Elf is positioned as a children’s craft art kit, it must pass LHAMA and display the “AP (Approved Product)” mark, indicating compliance with art material safety standards.

If the product is not a traditional art material, a TRA report should be provided to evaluate skin irritation, acute toxicity, potential allergenicity, and other chemical safety indicators.

The report should ensure safety under normal use (mixing, molding, skin contact).

One of these two documents can be chosen based on product positioning, but all chemical components must be assessed and core ingredient testing data cannot be missing.

Compliance Key Reminders

The three documents above are mandatory “hard barriers” for Magic Water Elf products entering the US market. Manufacturers should note:

(1) documents must be issued for specific product models and batches; generic certificates are invalid;

(2) labs must have CPSC recognition, otherwise test reports and the CPC based on them are invalid;

(3) complete original test data and documents must be retained for CPSC inspections and customs verification. Missing any document will result in prohibition of import or sale, and potential fines or product recalls.

2025-2026 Regulatory Updates & Safety Warnings

Recent actions by the U.S. Consumer Product Safety Commission (CPSC) have tightened regulatory oversight on water-gel products, aiming to mitigate potential safety hazards for consumers.

Suppliers must strictly adhere to the following updated rules to ensure compliance and avoid penalties or product recalls.

1. Water Bead Expansion Limits (Late 2025 Update)

The updated ASTM F963 standard has incorporated more rigorous measurement requirements for expanding materials like water beads.

To address the critical risk of intestinal blockage from ingestion—especially among children—manufacturers must ensure that water gels/beads, when fully expanded (per standard soaking conditions), do not exceed the size threshold that poses an ingestion hazard.

This update strengthens previous guidelines by clarifying expansion ratio testing methods and establishing mandatory compliance for all water-gel products distributed in the U.S. market.

2. Battery Compartment Safety (Kori Gey Recall 2026)

For kits equipped with LED light bases, electronic controllers, or other battery-powered components, the 2026 Kori Gey recall (triggered by button cell battery accessibility risks) has prompted enhanced safety mandates:

- Battery compartments must be secured with a non-removable screw, preventing easy access by children without tools.

- All battery-containing components must pass rigorous drop and impact tests (per CPSC specifications). These tests verify that button cell batteries remain inaccessible even after accidental drops or impacts, eliminating the risk of ingestion, chemical burns, or choking.

3. Permanent Tracking Labels

Pursuant to 15 U.S.C. § 2063(a)(5), both the water-gel product and its outer packaging must bear a permanent, non-removable tracking label.

The label must clearly display the following information to enable traceability in the event of safety issues:

- Full name of the manufacturer or private labeler (no abbreviations permitted).

- Exact production location (city, state/province, country) and production date (month/year minimum).

- Cohort information, including a unique batch, run, or lot number—critical for targeted recalls and root-cause analysis of safety defects.

2025-2026 Regulatory Updates & Safety Warnings

Recent actions by the U.S. Consumer Product Safety Commission (CPSC) have tightened regulatory oversight on water-gel products, aiming to mitigate potential safety hazards for consumers.

Suppliers must strictly adhere to the following updated rules to ensure compliance and avoid penalties or product recalls.

Water Bead Expansion Limits (Late 2025 Update)

The updated ASTM F963 standard has incorporated more rigorous measurement requirements for expanding materials like water beads.

To address the critical risk of intestinal blockage from ingestion—especially among children—manufacturers must ensure that water gels/beads, when fully expanded (per standard soaking conditions), do not exceed the size threshold that poses an ingestion hazard.

This update strengthens previous guidelines by clarifying expansion ratio testing methods and establishing mandatory compliance for all water-gel products distributed in the U.S. market.

Battery Compartment Safety (Kori Gey Recall 2026)

For kits equipped with LED light bases, electronic controllers, or other battery-powered components, the 2026 Kori Gey recall (triggered by button cell battery accessibility risks) has prompted enhanced safety mandates:

- Battery compartments must be secured with a non-removable screw, preventing easy access by children without tools.

- All battery-containing components must pass rigorous drop and impact tests (per CPSC specifications). These tests verify that button cell batteries remain inaccessible even after accidental drops or impacts, eliminating the risk of ingestion, chemical burns, or choking.

Permanent Tracking Labels

Pursuant to 15 U.S.C. § 2063(a)(5), both the water-gel product and its outer packaging must bear a permanent, non-removable tracking label.

The label must clearly display the following information to enable traceability in the event of safety issues:

- Full name of the manufacturer or private labeler (no abbreviations permitted).

- Exact production location (city, state/province, country) and production date (month/year minimum).

- Cohort information, including a unique batch, run, or lot number—critical for targeted recalls and root-cause analysis of safety defects.

Key Components and Chemical Safety

Intent: Cognitive / Educational

Magic Water Elf kits are primarily composed of food-grade chemicals, but purity levels must be verified for toy safety.

- Magic Gel: Typically a solution of Sodium Alginate mixed with pigments (glitter or glow-in-the-dark additives).

- Setting Powder: Calcium Lactate or Calcium Chloride. Calcium Lactate is preferred for younger children as it is less irritating to the skin.

- Safety Requirement: All pigments and additives must be free of lead, phthalates, and cadmium.

How to Verify a Manufacturer’s Compliance Claim?

This guide provides actionable steps to verify a manufacturer’s compliance claims, supporting informed decision-making before finalizing partnerships or bulk orders, especially for products subject to U.S. consumer safety regulations.

Request a Lab ID

The first critical step is to obtain the laboratory identification information associated with the manufacturer’s compliance testing. Specifically, ask the manufacturer to provide the report number issued by a CPSC-accepted laboratory—the U.S. Consumer Product Safety Commission (CPSC) maintains a list of accredited labs whose test results are legally recognized.

Once you have the report number, verify its validity directly through the official CPSC website (CPSC.gov). Navigate to the relevant section for laboratory and test report verification (typically under the “Compliance” or “Safety Certification” tab). Input the report number to cross-check details such as the testing laboratory’s accreditation status, the date of the test, the product model tested, and whether the report corresponds to the exact product you intend to purchase. If the report number is unsearchable, expired, or linked to a non-accredited lab, the manufacturer’s compliance claim is unsubstantiated, and you should request additional documentation or reconsider the partnership.

Check for ASTM F963-23

ASTM F963 is the primary standard for toy safety in the United States, covering physical, mechanical, chemical, and flammability requirements. It is essential to confirm that the test report references the 2023 version (ASTM F963-23) and not outdated iterations such as 2017 or 2016.

Outdated versions lack updates to address emerging safety hazards, such as new chemical restrictions or revised physical safety criteria for small components.

Carefully review the test report’s Applicable Standards section to ensure the exact 2023 version is cited.

If the manufacturer uses an older version, they may not meet current legal requirements, exposing your business to regulatory penalties and safety risks. Request retesting to ASTM F963-23 before proceeding.

Physical Sample Testing

Even with a valid lab report, conduct independent physical sample testing to validate compliance before finalizing a bulk order.

This step mitigates the risk of the manufacturer providing falsified reports or producing non-compliant products in mass production.

- Small Parts Test (for molds): If the product or its components (e.g., mold-cast parts) are intended for children under 3 years old, perform a small parts test using the CPSC-approved small parts cylinder. The test checks if any component can fit entirely into the cylinder (2.25 inches in diameter and 1.25 inches deep), which would pose a choking hazard. Ensure all mold-produced parts pass this test, with no loose or detachable small components under normal use and abuse conditions.

- Leach Test (for gels): For gel-based products (e.g., toy gels, decorative gels), conduct a leach test to measure the migration of harmful substances (e.g., heavy metals, phthalates) into a simulated bodily fluid environment. Follow CPSC or ASTM protocols for sample preparation, extraction, and chemical analysis. The leachate must meet strict limits for toxic substances—exceeding these limits renders the product non-compliant and unsafe for consumer use.

Engage a third-party CPSC-accepted laboratory for this independent testing to ensure impartiality and legal recognition of results. If samples fail, notify the manufacturer and demand corrective action; only proceed with the bulk order if retested samples pass all requirements.

Conclusion

Ensuring CPSIA compliance is critical for Water Elf Kits targeting U.S. consumers. Leading suppliers provide CPCs, ASTM F963-23 test reports, and LHAMA/TRA certifications, confirming chemical, mechanical, and flammability safety.

Suppliers like Jaredrise, Alpha, Nicella, and Early Light Industrial combine compliance expertise with scalable OEM/ODM capacity, delivering stable gel formulations, packaging, and production consistency.

Updated regulations address water bead expansion, battery safety, and permanent labeling, reinforcing risk mitigation.

Verification steps—confirming lab accreditation, reviewing relevant ASTM standards, and conducting independent sample tests—are essential before bulk orders.

By following these protocols, brands can ensure legally compliant, child-safe products, minimize import and retail risks, and leverage reliable manufacturers for private labeling or bulk supply. Strategic selection of suppliers balances compliance stability, production scale, and product differentiation for U.S. market success.