Sourcing preschool toys is no longer just about price. Choosing the wrong preschool toy suppliercan lead to safety issues, failed compliance checks, delayed shipments, and serious damage to your brand reputation.

In today’s market, buyers must work with a qualified educational toy manufacturer that meets standards such as EN71, ASTM F963, and CPSIA. An unreliable factory may use unsafe materials, provide incomplete certifications, or lack proper quality control systems.

In 2026, with stricter platform rules and customs inspections, selecting a reliable toy factory is more important than ever. One compliance failure can result in product recalls or account suspension.

In this guide, you will learn how to evaluate suppliers, verify certifications, and choose long-term manufacturing partners for safe and profitable sourcing.

Understand 2026 Safety and Compliance Requirements

For importers and brand owners, safety and compliance are the biggest risks when sourcing preschool building blocks.

In 2026, global regulations are becoming stricter, and customs inspections are more detailed. Working with a non-compliant supplier may result in shipment delays, fines, product recalls, or permanent market bans.

A professional preschool toy supplier must be able to provide complete, valid, and up-to-date certification documents for your target market.

Mandatory Certifications for Preschool Building Blocks

Before placing any order, buyers should confirm that the educational toy manufacturer can meet the following core standards:

- EN71 (Europe)

Controls mechanical safety, chemical content, and flammability for toys sold in the EU. - ASTM F963 (USA)

The main safety standard for toys in the United States, covering physical hazards and toxic substances. - CPSIA / CPC (USA)

Requires Children’s Product Certificate (CPC) and limits on lead, phthalates, and heavy metals. - ISO 9001

Shows that the factory has a standardized quality management system, improving production stability. - REACH (EU Chemicals Regulation)

Restricts harmful substances in plastic, paint, and coatings used in toys.

A reliable toy factory should proactively provide test reports, certificates, and compliance summaries without hesitation.

Reference: EU Toy Safety Directive

How to Verify Certificates Are Authentic?

Not all certificates provided by suppliers are real or valid. Buyers should always conduct basic verification.

- Check Government or Official Databases

Many certifications can be verified through official websites or notified body platforms. - Confirm with Third-Party Testing Labs

Contact recognized labs such as SGS, TÜV, Intertek, or BV to verify report numbers. - Identify Common Fake Certificate Signs

- No laboratory logo or stamp

- Expired test dates

- Incorrect product photos

- Missing report ID numbers

- Only “sample reports” without company name

If a supplier refuses verification, it is a high-risk signal.

Reference: CPSC Testing & Certification Guide

Regional Market Compliance Differences

Different markets have different import and compliance requirements. Buyers must prepare documents based on their target region.

USA

- ASTM F963 + CPSIA + CPC

- Tracking labels required

- Mandatory third-party testing

European Union

- EN71 + CE marking

- Declaration of Conformity

- REACH compliance

United Kingdom

- UKCA marking

- Similar to EN71 but requires UK documentation

Australia

- AS/NZS ISO 8124

- Mandatory safety labeling

- Customs inspection priority for toys

Each market has its own import procedures and documentation standards. A professional preschool toy supplier should understand these differences and help buyers prepare complete files before shipment.

Evaluate Factory Qualifications and Manufacturing Capability

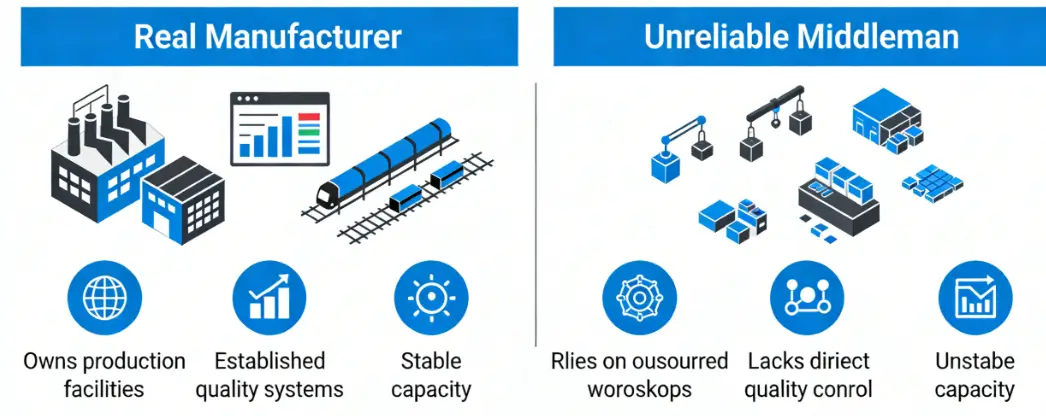

Choosing a real manufacturer instead of an unreliable middleman is critical for long-term sourcing success. In 2026, buyers must verify whether a supplier truly owns production facilities, quality systems, and stable capacity, rather than relying on outsourced workshops.

A qualified preschool toy supplier should be transparent about its factory conditions, equipment, and audit records.

Factory Scale and Infrastructure

A professional educational toy manufacturer should have complete in-house production facilities.

Key areas to check include:

- Production Area

Well-organized workshops with clear material flow and safety management. - Injection Molding Machines

Modern molding machines with stable output and regular maintenance records. - Mold Workshop

In-house mold design and repair capability for faster customization and cost control. - Assembly Lines

Standardized assembly lines with quality checkpoints and trained operators.

If a supplier cannot show real photos, videos, or live factory tours, the risk level is high.

Manufacturer vs Trading Company

Many “factories” online are actually trading companies. Understanding the difference helps you reduce supply risks.

Comparison Table

| Item | Real Manufacturer | Trading Company |

|---|---|---|

| Own Factory | Yes | No |

| Equipment | In-house | Outsourced |

| Quality Control | Internal system | Depends on partners |

| Customization | Strong | Limited |

| Price Control | Stable | Markup added |

Trading Company Risks

- Limited control over production

- Unstable quality

- Difficult problem resolution

- Higher compliance risk

Manufacturer Advantages

- Direct quality management

- Faster sampling

- Better technical support

- Long-term cooperation stability

Cost Differences

Trading companies usually add 10%–30% margin. Working directly with a reliable toy factory improves cost efficiency and negotiation power.

Factory Audit Checklist

Before mass production, buyers should conduct a structured factory audit.

1.On-Site Audit

Best option for large orders.

2.Checklist:

- Business license verification

- Production line inspection

- QC procedures review

- Worker training records

- Material warehouse check

3.Video Audit

Suitable for remote buyers.

4.Checklist:

- Live workshop walkthrough

- Machine operation demo

- Warehouse overview

- Packaging process review

- Real-time Q&A

5.Third-Party Inspection

Recommended for high-risk projects.

Common agencies:

- SGS

- TÜV

- Intertek

- BV

Services include:

- Factory capability assessment

- Social compliance audit

- Production monitoring

- Pre-shipment inspection

Assess Product Quality and Material Safety

For preschool toys, long-term reliability and child safety are non-negotiable. Buyers must ensure that their preschool toy supplier uses safe materials, robust design, and thorough testing. Poor quality or unsafe materials can lead to recalls, fines, or brand damage.

A professional educational toy manufacturer should provide full transparency on materials, testing reports, and quality standards.

Raw Material Selection

High-quality materials are the foundation of safe toys. Key materials include:

- ABS (Acrylonitrile Butadiene Styrene) – durable, impact-resistant, widely used for building blocks.

- PP (Polypropylene) – lightweight, non-toxic, chemical-resistant plastic.

- Food-Grade Plastics – suitable for teething toys and items that children may put in their mouths.

- Eco-Friendly Materials – non-toxic, recyclable, or biodegradable plastics for environmentally conscious brands.

A reliable factory provides material certificates, MSDS sheets, and traceable sourcing.

Structural Design and Durability Testing

A well-designed toy must withstand real-world use. Essential tests include:

- Drop Test – ensures pieces do not break or create sharp edges if dropped.

- Biting Force Test – simulates chewing and ensures no small parts break off.

- Connection Strength – checks interlocking blocks and assembly points for durability.

Factories should maintain test records and allow buyers to inspect sample reports before production.

Color, Coating, and Chemical Safety

Toys must meet strict chemical safety standards. Key areas:

- Heavy Metals – lead, cadmium, and chromium must meet EN71/ASTM limits.

- Phthalates – used in soft plastics; many markets now ban harmful phthalates.

- Lead Content – especially in paint or colored plastics, must comply with CPSIA and REACH.

A professional toy factory should provide third-party lab testing certificates for each batch, ensuring every product shipped is safe for children.

Sample Evaluation and Trial Order Strategy

Even after verifying a factory’s certifications and quality systems, buyers should never skip sample evaluation.

Requesting and testing samples before mass production is the most effective way to reduce sourcing risks and ensure product consistency.

A professional preschool toy supplier will support sample requests and provide detailed documentation for evaluation.

How to Request Professional Samples?

When requesting samples, specify your needs clearly:

- Sample Specifications – exact dimensions, colors, and materials for accurate testing.

- Branding Samples – include logos, labels, or custom prints to evaluate real-world branding effects.

- Packaging Samples – verify box quality, inserts, and labeling for market-ready presentation.

A reliable educational toy manufacturer will provide both unbranded and branded samples for full evaluation.

Sample Quality Evaluation Checklist

When evaluating samples, buyers should check:

- Dimensions – confirm all pieces match design specifications.

- Color Consistency – ensure uniform color across multiple pieces or batches.

- Surface Finish – smooth edges, no burrs or sharp points.

- Fit Accuracy – blocks, connectors, and assembly parts should fit precisely.

Use this checklist to detect manufacturing defects before placing larger orders.

Trial Orders and Pilot Production

After sample approval, a trial order or small batch production helps verify factory reliability and market response:

- Small Batch Testing – order a limited quantity to check production consistency.

- Market Feedback – test your products with target customers or local distributors.

- Risk Control – adjust specifications, packaging, or sourcing decisions based on pilot results before scaling up.

A strategic trial order reduces the risk of defects, compliance failures, or unsold inventory, ensuring smooth mass production.

Pricing Structure, MOQ, and Cost Transparency

One of the most common risks in sourcing preschool toys is hidden costs. Understanding a supplier’s pricing structure, minimum order quantity (MOQ), and full cost transparency is essential to avoid surprises and maintain profitability.

A professional preschool toy supplier provides clear pricing and explains each component of the quote.

Common Pricing Models in Toy Manufacturing

When comparing quotes, buyers should be familiar with standard international pricing terms:

- FOB (Free on Board) – price includes manufacturing and delivery to the port; buyer handles shipping and insurance.

- EXW (Ex Works) – price includes factory cost only; buyer handles everything else.

- CIF (Cost, Insurance, Freight) – price includes shipping and insurance to the buyer’s port.

- DDP (Delivered Duty Paid) – price includes delivery to the buyer’s warehouse, with all duties and taxes handled by the supplier.

Choosing the right pricing model affects total cost and risk allocation.

Hidden Costs to Watch For

Some suppliers quote low unit prices but add extra fees later. Common hidden costs include:

- Mold Fees – sometimes charged per design or updated version.

- Testing Fees – third-party lab tests for compliance.

- Packaging Costs – branded packaging or export-ready cartons.

- Rework Costs – corrections due to quality defects.

A reliable educational toy manufacturer will provide a detailed cost breakdown upfront to avoid surprises.

How to Compare Supplier Quotes Fairly

When evaluating multiple quotes, focus on both value and transparency:

- Cost Breakdown Analysis – review each cost component: materials, labor, packaging, testing, shipping.

- Value vs Price – the cheapest price is not always the best; consider supplier reliability, compliance, and long-term partnership benefits.

A structured comparison ensures informed decision-making and prevents sourcing risks before production begins.

Communication, Project Management, and Service Capability

Long-term sourcing success depends not only on product quality and compliance but also on supplier communication and service capability.

A professional preschool toy supplier ensures smooth coordination, timely updates, and reliable support throughout the project lifecycle.

Response Speed and Language Skills

Efficient communication is crucial when working with overseas suppliers:

- Email Response Time – fast replies indicate reliability and respect for deadlines.

- Technical Communication – clear understanding of product specifications, test requirements, and production constraints.

- Documentation Quality – precise, complete, and professional documents for orders, certificates, and contracts.

Suppliers with strong communication skills reduce misunderstandings and prevent costly delays.

Order Management and Production Tracking

Professional manufacturers provide structured order management to keep projects on schedule:

- Production Schedules – clear timelines for each stage: mold making, trial production, mass production.

- Quality Checkpoints – systematic inspections at material receipt, mid-production, and pre-shipment.

- Shipment Coordination – accurate packing, labeling, and logistics coordination to avoid delivery issues.

Reliable tracking systems give buyers confidence in predictable lead times.

After-Sales and Complaint Handling System

Even with thorough evaluation, occasional issues may arise. Buyers should confirm that suppliers provide strong after-sales support:

- Defect Replacement – fast replacement or rework of defective products.

- Recall Support – guidance and assistance if compliance issues or recalls occur.

- Warranty Policy – clear coverage terms for products and components.

A robust service system ensures smooth resolution, reduces business risk, and supports long-term partnerships.

Common Mistakes Buyers Make When Choosing Toy Suppliers

Even experienced buyers sometimes fall into sourcing traps that compromise safety, quality, and profitability. Understanding these common mistakes helps you make smarter decisions and choose a reliable preschool toy supplier for long-term success.

Typical Mistakes

- Choosing the Lowest Price Only

Focusing solely on unit cost often leads to quality problems, hidden fees, or compliance failures. The cheapest supplier is rarely the safest choice. - Skipping Factory Audits

Not inspecting the factory or requesting on-site/video audits increases the risk of dealing with trading companies posing as manufacturers. - Ignoring Compliance Documents

Accepting certificates at face value without verification can result in regulatory issues, recalls, or shipment rejections in key markets. - No Quality Agreement

Without a clear quality agreement, there’s no standard for product defects, tolerances, or testing requirements. Disputes become harder to resolve. - No Backup Supplier

Relying on a single supplier creates vulnerability if production delays, quality issues, or compliance failures occur. Always maintain alternatives to reduce risk.

A professional educational toy manufacturer will guide buyers to avoid these mistakes, provide transparent documentation, and ensure predictable production and delivery.

Why Professional Buyers Choose Jaredrise?

When sourcing preschool toys, professional buyers look for reliability, experience, and proven quality.

Jaredrise has been serving the global market for years as a trusted preschool toy supplier and educational toy manufacturer, delivering products that meet international standards and buyer expectations.

Manufacturing Experience

With decades of experience in toy production, Jaredrise combines modern facilities, skilled staff, and standardized processes to ensure consistent output for every order.

Export Markets

Jaredrise serves clients across the US, EU, UK, and Australia, familiar with regional compliance requirements and import regulations, making cross-border sourcing seamless.

Certifications

All products are tested and certified according to EN71, ASTM F963, CPSIA, ISO 9001, and REACH standards, giving buyers confidence in material safety and legal compliance.

Quality Control System

From raw material selection to assembly and final shipment, Jaredrise implements rigorous quality checkpoints, in-house lab testing, and trial order evaluations to maintain high standards.

Client Testimonials

Many long-term partners praise Jaredrise for transparency, timely delivery, and responsive communication, emphasizing the trust built over repeated collaborations.

By focusing on experience, compliance, and transparent processes, Jaredrise helps buyers minimize risk and simplify the sourcing journey, allowing professional teams to concentrate on market growth rather than production issues.

Reference: Jaredrise Company Profile & Certifications

Conclusion

Selecting the right supplier goes beyond cost—it’s about safety, quality, and reliability.

By following this guide, buyers can minimize risks, secure certified preschool toys, and build lasting partnerships with trusted manufacturers.