Oil-based paint markers remain a reliable choice for industrial, commercial, and DIY applications, especially when users need durability and strong opacity.

Many beginners underestimate safety factors such as ventilation and VOC exposure, which can affect comfort and long-term usability.

This guide explains safety practices, selection criteria, and surface techniques in clear, actionable steps.

The content also includes neutral industry data, checklists, and experience-based insights to support better decision-making.

What Are Oil-Based Paint Markers?

Oil-based paint markers are solvent-filled marking tools designed for strong adhesion and long-lasting color.

They differ from water-based markers because their pigments are suspended in oil-solvent carriers that bond more aggressively to surfaces.

This makes them suitable for metal, plastic, rubber, stone, ceramic, and outdoor applications.

Users often prefer oil markers when they need durability, scratch resistance, and opacity on dark or non-porous materials.

Because the paint layer cures into a hard film, the markings remain stable in environments with heat, moisture, or abrasion.

Industry notes indicate that most commercial solvent markers fall within a VOC content range of 30–70 g/L, depending on tip size and solvent formulation.

Users should therefore understand ventilation importance early on.

Read moe:Acrylic Markers vs Paint Markers:What’s the Real Difference?

Are Oil-Based Paint Markers Safe for Daily Use?

Oil-based paint markers are safe for daily use when users maintain airflow and avoid prolonged exposure to concentrated vapors.

The solvent smell indicates active evaporation, so rooms with poor ventilation can accumulate odors quickly.

Beginners often underestimate how enclosed spaces amplify VOC concentration, especially when using multiple markers or priming the nib repeatedly.

Adequate ventilation lowers the intensity and helps maintain comfort during long sessions.

According to general workplace guidelines from OSHA, acceptable ventilation reduces solvent odor buildup and prevents discomfort during routine tasks.

While markers are consumer-safe, smart usage habits improve the writing experience significantly.

What Safety Risks Should Beginners Pay Attention To?

Beginners should pay attention to solvent exposure, odor accumulation, and heat sensitivity when using oil-based paint markers.

The main risks come from poorly ventilated rooms or improper storage rather than from the marker itself.

Strong odors usually mean the solvent is evaporating faster than the room can disperse it.

Users should open windows, use fans, or write near an open door for better airflow.

Storing markers near heat sources also increases evaporation, leading to thicker paint or clogged nibs.

Skin contact is usually minimal, but repeated cleaning of the nib with bare hands can leave solvent residue. Wearing simple gloves during maintenance improves comfort without changing handling quality.

How Can You Use Oil-Based Paint Markers Safely?

You can use oil-based paint markers safely by maintaining steady airflow, capping the marker promptly, and storing it away from heat.

These steps keep odors low and ensure smoother writing performance.

Practical habits include shaking markers outdoors or near a window, wiping the nib with a disposable cloth instead of bare fingers, and resting between long marking sessions.

Users who follow these habits often notice clearer lines and more consistent ink flow.

Safety Checklist

- Maintain open windows or use a small fan.

- Avoid using markers in enclosed rooms.

- Cap markers immediately after writing.

- Store markers horizontally to prevent tip flooding.

- Keep away from heat sources and direct sunlight.

Why Is Ventilation Important When Using Oil-Based Markers?

Ventilation is important because it disperses VOCs and keeps the workspace comfortable during long writing sessions.

Even small rooms can accumulate odors quickly once the solvent begins to evaporate.

Airflow also stabilizes nib performance, as excess solvent vapor can slightly thicken the paint over time.

Users working near windows generally report smoother lines and fewer clogs during intensive marking tasks.

Neutral industry data shows that elevated indoor VOC levels occur faster in rooms below 10–12 m² when airflow is restricted, making ventilation an essential practice rather than an optional habit.

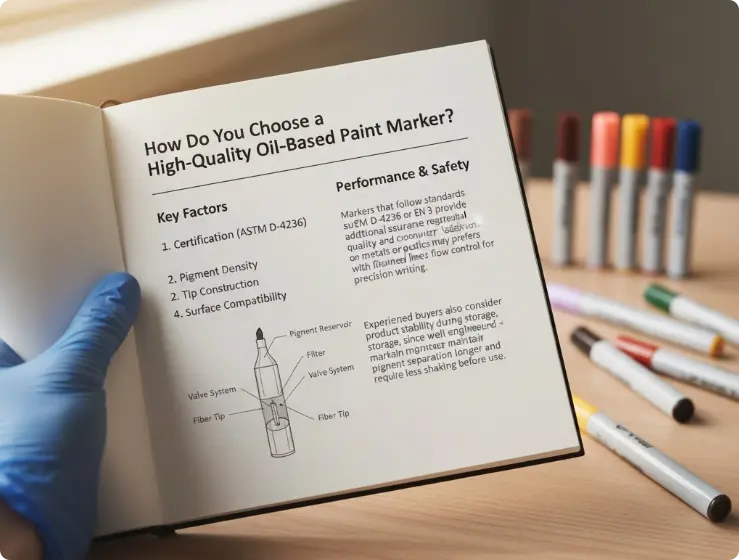

How Do You Choose a High-Quality Oil-Based Paint Marker?

You can choose a high-quality oil-based paint marker by focusing on certification, pigment density, tip construction, and surface compatibility.

These factors help ensure consistent writing and long-term performance.

Markers that follow standards such as ASTM D-4236 or EN 71-3 provide additional assurance regarding material quality and consumer safety.

Users who work on metals or coated plastics may prefer markers with fine-tuned flow control for precision writing.

Experienced buyers also consider product stability during storage, since well-engineered markers maintain pigment separation longer and require less shaking before use.

We offer Acrylic Paint Marker Set Wholesale: No MOQ Stock + Custom Branding Options to meet the needs of buyers seeking cost-effective bulk marker sets with personalized branding and no minimum order constraints.

How Should You Apply Oil-Based Paint Markers on Different Surfaces?

You should apply oil-based paint markers on different surfaces by adjusting pressure, cleaning the surface first, and selecting the right nib size.

This approach prevents smudging and improves long-term adhesion.

Metal surfaces accept paint best when wiped with a dry cloth to remove dust or oil.

Plastic requires lighter pressure because the paint tends to sit on top before curing.

Wood absorbs more pigment, so slow strokes help maintain opacity.

Users working outdoors often prefer medium or broad tips, which allow stronger, more visible lines that resist fading in sunlight and weather conditions.

How Do Oil-Based Paint Markers Compare to Water-Based Alternatives?

Oil-based paint markers compare favorably to water-based alternatives when users need durability, opacity, and resistance to outdoor conditions.

Water-based markers excel indoors, but they are less resilient on non-porous surfaces.

Oil-based markers form a harder cured layer, making them suitable for industrial tags, labeling, or long-term crafts.

Water-based markers are easier to clean and have minimal odor, which makes them appealing for indoor hobby work.

Users should choose based on surface type, environment, and desired permanence rather than relying on a single material category.

FAQ: Common Questions About Oil-Based Paint Markers

Do oil-based markers smell stronger than water-based markers?

Oil-based markers smell stronger because solvents evaporate faster than water. The odor is normal and can be controlled through good ventilation.

Are oil-based paint markers suitable for children?

Oil-based markers are not recommended for young children because the solvent odor may cause discomfort in enclosed spaces.

How long should a room be ventilated after use?

Most rooms clear odors within 10–20 minutes with open windows or a fan running.

Why does the nib flood when shaken?

The nib floods when the internal pressure increases from shaking. Shaking gently and keeping the cap on helps reduce this issue.

About Jaredrise

Jaredrise provides industrial marking tools engineered for stable flow, strong adhesion, and durable color performance.

With years of experience in surface marking materials, the company focuses on practical reliability rather than promotional claims.

Its export operations serve customers across North America, Europe, and Asia, supplying markers that comply with recognized standards such as ASTM D-4236.

Product lines from Jaredrise emphasize consistency, surface versatility, and ease of handling for both beginners and experienced users.

Jaredrise continues to refine solvent-control and pigment-stability processes to support customers who need dependable, long-term marking results in varied working environments.