Sourcing Magic Water Elf Kits from China is often perceived as low-cost and straightforward.

In practice, factory pricing represents only part of the total expense.

For importers, private-label sellers, and toy distributors, understanding the full cost breakdown is essential to avoid margin erosion, compliance risks, and unexpected losses.

This report provides a data-backed cost breakdown for sourcing Magic Water Elf Kits from China,based on common sourcing scenarios observed during 2024–2025.

The analysis reflects real-world procurement conditions rather than theoretical estimates.

Executive Cost Summary

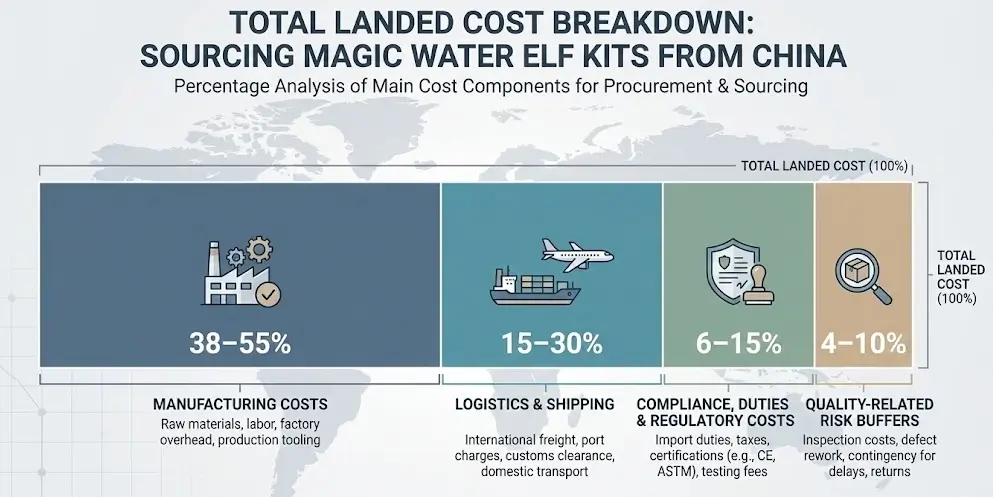

The total landed cost of sourcing Magic Water Elf Kits from China typically includes manufacturing (38–55%), logistics (15–30%), compliance and duties (6–15%), and quality-related risk buffers (4–10%).

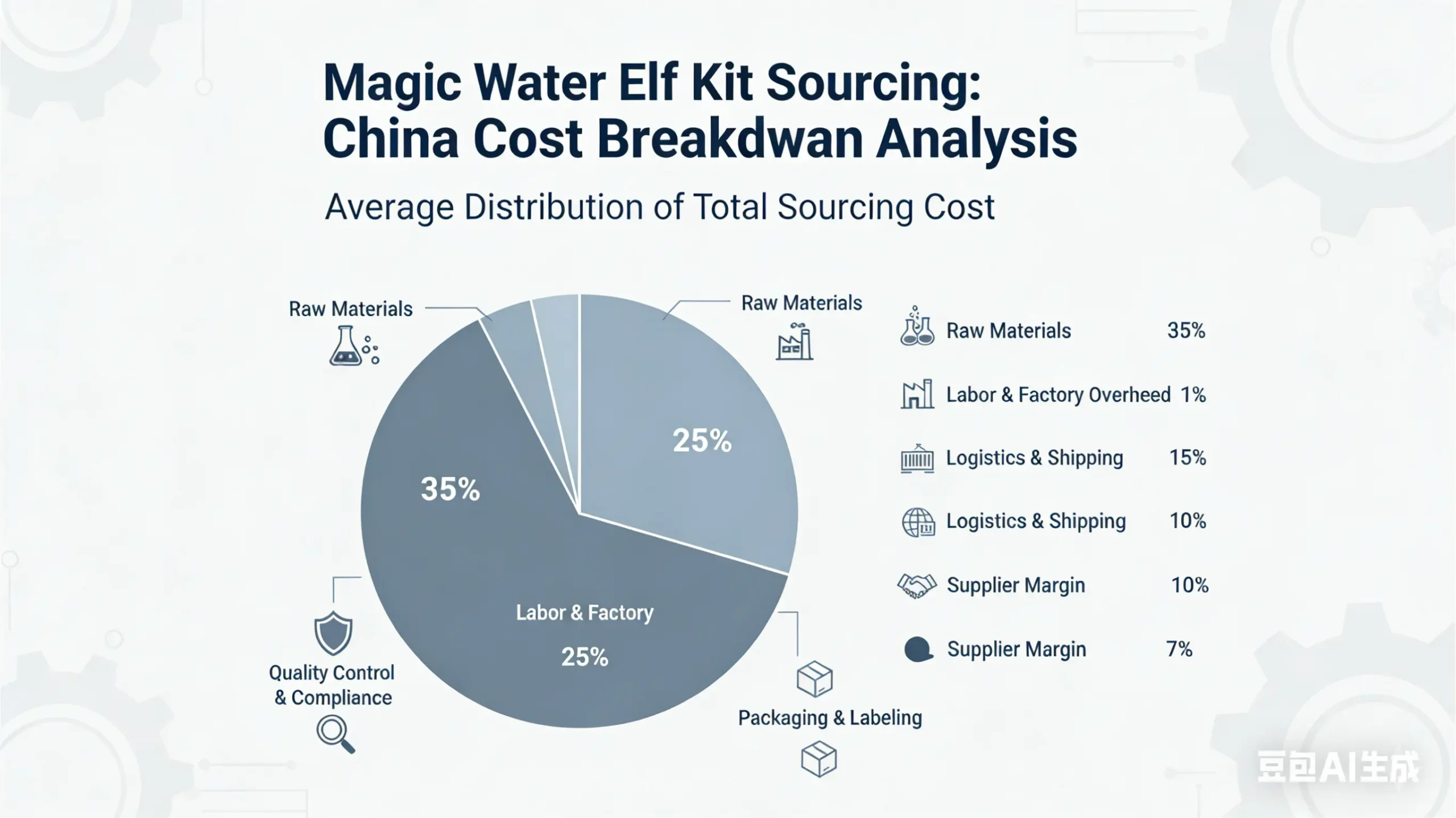

Average Total Landed Cost Structure (2024–2025)

- Manufacturing & packaging: 38–55%

- Logistics & international freight: 15–30%

- Import duties, taxes & compliance: 6–15%

- Quality control, inspections & risk buffer: 4–10%

In real sourcing projects, buyers frequently underestimate non-factory costs by 20–35%, particularly on first-time imports.

The most common mistake is assuming the factory’s FOB quotation represents the final procurement cost.

Procurement Decision Example

1. Application Example: Creative Play

2. Case Reference: OEM Customization

3. Procurement Decision Example

4. Cost Control Case

Understanding the cost structure is essential for budgeting. The Cost Breakdown for Sourcing Magic Water Elf Kits from China explains materials, packaging, shipping, and import fees in detail.

5. Quality Management Example

To ensure product safety and reliability, the Common Quality Issues in Magic Water Elf Kits and How Manufacturers Control Them shows real-world quality control measures applied by leading manufacturers.

6. Production and Customization Application

Learn how materials, production processes, and customization options affect product quality in the Magic Water Elf Kit Manufacturer: Production Process, Materials, and Custom Options.

7. Top Manufacturer Reference

If you plan to source directly, check out the Top 5 Magic Water Elf Kits Manufacturers for Kids in 2025 for reliable suppliers.

8. Choosing a Reliable Manufacturer Example

Use the How to Choose a Reliable Magic Water Elf Kit Manufacturer in China guide to evaluate credibility, production capacity, and compliance.

9. Bulk Order Evaluation Case

For large orders, the How to Evaluate a Magic Water Elf Kit Manufacturer for Bulk Orders explains supplier assessment and cost analysis for volume procurement.

10. Beginner Guide Application

New users can learn how to start with Magic Water Elf Kits via the What Is a Magic Water Elf Kit? Complete Guide for Beginners, covering gameplay, kit contents, and educational value.

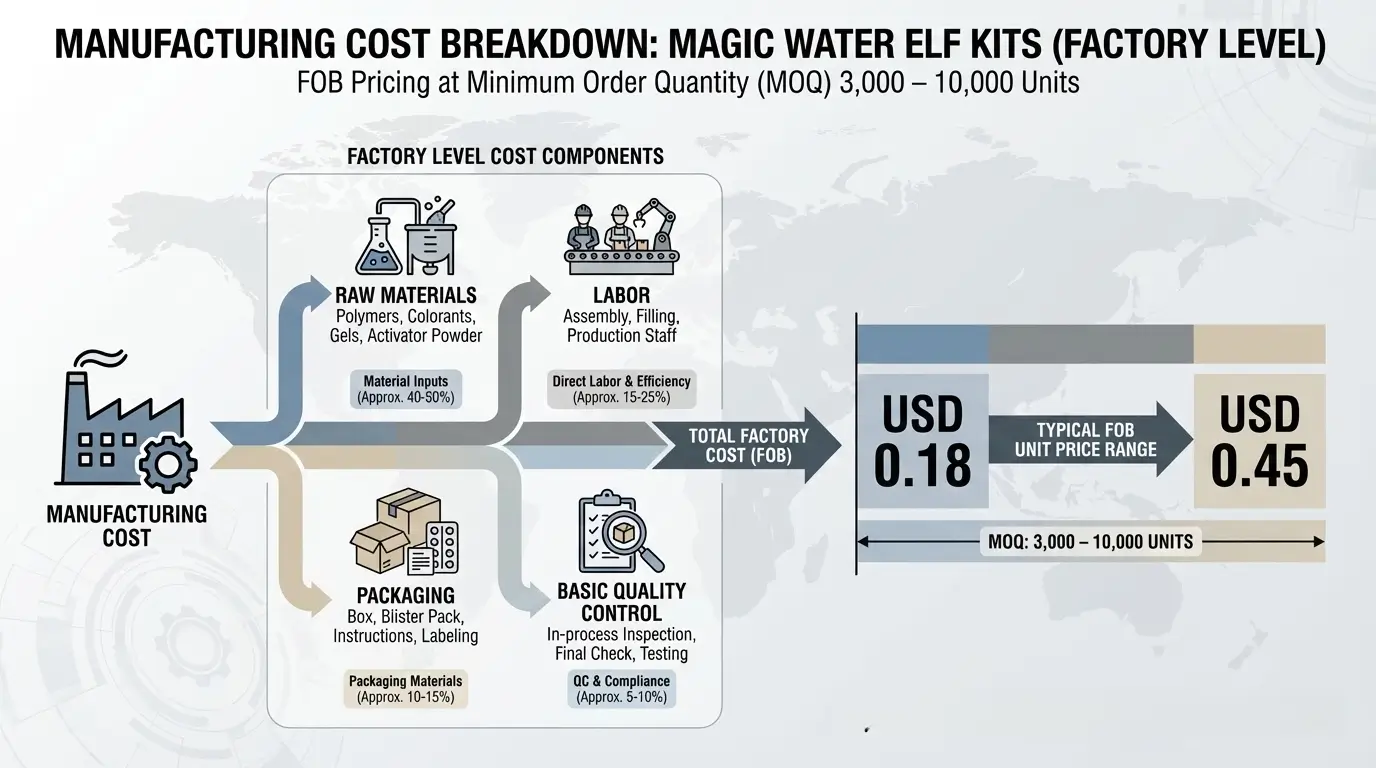

Manufacturing and Product Cost Breakdown

Manufacturing cost refers to the factory-level expense of producing Magic Water Elf Kits, including raw materials, labor, packaging, and basic quality controls.

Typical FOB unit prices range from USD 0.18 to 0.45 per kit at MOQs between 3,000 and 10,000 units.

Unit Production Cost at Factory Level

The factory price of Magic Water Elf Kits varies depending on material quality, automation level,and order volume.

Typical FOB unit price (MOQ 3,000–10,000 units): USD 0.18 – 0.45 per kit

- Super absorbent polymer (SAP) grade and purity

- Capsule size uniformity and color consistency

- Automated vs semi-manual filling lines

- Scrap rate control during encapsulation

Factories operating integrated molding and filling lines usually show 8–12% lower unit cost volatility compared with suppliers that outsource key components.

Tooling, Packaging, and Customization Costs

- Private mold fee (one-time): USD 800 – 2,500

- Custom retail packaging (per unit): USD 0.03 – 0.08

- Instruction manuals & branding inserts: USD 120 – 300 per design

Experienced importers typically amortize tooling costs over three to five reorder cycles rather than treating them as a one-time loss.

Logistics and International Shipping Costs

Logistics costs represent a significant portion of the total sourcing expense because Magic Water Elf Kits are volume-sensitive rather than weight-sensitive products.

Sea freight typically accounts for 15–30% of total landed cost, depending on packaging density and shipment size.

Freight Cost by Shipping Method (2025 Market Rates)

- Sea freight (LCL): USD 1,200 – 2,000 per CBM

- Sea freight (FCL 20ft): USD 2,800 – 4,200

- Air freight: USD 5.5 – 8.5 per kg

Magic Water Elf Kits are lightweight but volume-sensitive.

Packaging efficiency directly affects per-unit freight cost,making sea freight the dominant shipping method for commercial orders.

Inland China Logistics and Export Handling

- Factory-to-port trucking: USD 120 – 350

- Export customs declaration & documentation: USD 180 – 300

- Port handling charges (THC): USD 150 – 280

These expenses are largely fixed per shipment,which explains why smaller orders often carry disproportionately high logistics costs.

Import Duties, Taxes, and Regulatory Compliance

Import duties and compliance costs include customs duties, VAT, and mandatory toy safety certifications required for legal market entry.

For Magic Water Elf Kits classified under HS Code 9503.00, total compliance and duty costs usually range from 6% to 15% of the declared value.

Customs Duties and HS Code Classification

Magic Water Elf Kits are generally classified under HS Code 9503.00 (toys).

- U.S. import duty: 0–6.5%

- EU import VAT: 19–22% (recoverable for VAT-registered entities)

Incorrect HS classification frequently increases duty exposure by two to three times, especially when kits include accessories or promotional packaging.

Mandatory Certifications and Testing Costs

- ASTM F963 (USA): USD 600 – 1,200

- CPSIA & CPC documentation: USD 300 – 600

- EN71 (EU): USD 700 – 1,500

Compliance costs are incurred per SKU, not per shipment.

Reducing SKU fragmentation can lower long-term compliance expenses by 15–30%.

Quality Control and Risk-Related Costs

More than 70% of quality failures in water-based toy kits originate from uncontrolled raw material substitution during production.

Third-Party Inspection and QA Expenses

- Pre-shipment inspection (PSI): USD 180 – 350

- During production inspection (DPI): USD 250 – 450

- Random batch laboratory testing: USD 300 – 800

Industry inspection data indicates that more than 70% of quality failures in water-based toy kits originate from uncontrolled raw material substitution.

Payment Terms, Currency, and Risk Buffer

Standard payment terms typically require a 30% deposit and 70% balance before shipment.

- RMB–USD exchange fluctuation: ±2–5% annually

- Recommended contingency buffer: 5–8% of order value

Professional buyers treat currency fluctuation and rework risk as predictable cost components,not exceptional events.

Sample Cost Breakdown Table

Total sourcing cost decreases significantly once order volume exceeds 8,000 units due to logistics efficiency and fixed-cost dilution.

Estimated Total Cost by Order Volume

- 3,000 units: USD 1,950 – 2,600

- 5,000 units: USD 2,800 – 3,700

- 10,000 units: USD 4,900 – 6,200

Once order volume exceeds approximately 8,000 units,logistics efficiency typically improves, reducing per-unit landed cost by 18–25%.

Cost Optimization Insights from Real Sourcing Projects

- Consolidating multiple SKUs under one compliance test

- Switching from LCL to shared or full container loads

- Pre-approving material substitutions through lab testing

- Negotiating long-term freight agreements

- Planning payments to reduce foreign exchange exposure

Across multiple sourcing projects, these measures typically reduce total landed cost by 8–15% without compromising quality or compliance.

What Professional Buyers Consistently Factor In?

- Factory pricing represents only about half of total sourcing cost

- Compliance and logistics largely determine long-term profitability

- Data-driven planning outperforms aggressive price negotiation

- The lowest quote rarely produces the lowest landed cost

Buyers who approach sourcing as a structured cost system,rather than a price comparison exercise, achieve more stable margins and fewer operational disruptions.