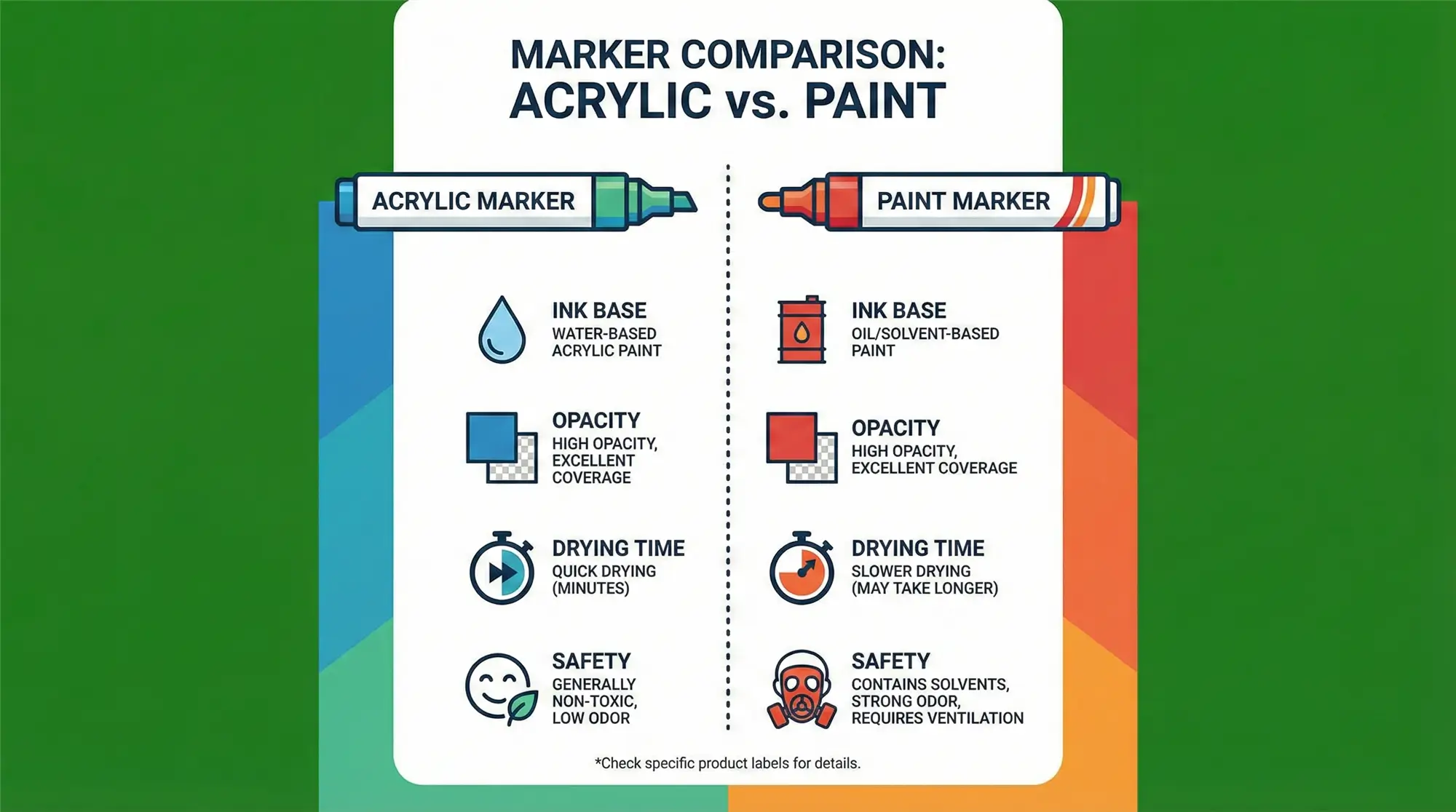

Acrylic markers and general paint markers differ mainly in ink composition, safety, opacity, and suitability for various surfaces, and understanding these differences is essential for choosing the right product or sourcing reliably from China.

Most buyers discover this distinction only after testing multiple samples, because suppliers use “paint marker” as a broad category covering oil-based, solvent-based, acrylic, and pigment-ink pens.

This article provides a clear comparison, quantifiable quality checks, and practical buying guidance based on years of sourcing experience in the Chinese stationery supply chain.

It also includes supplier-grade insights from Jaredrise, a manufacturer familiar with export standards and compliance for US/EU markets.

What Are Acrylic Paint Markers?

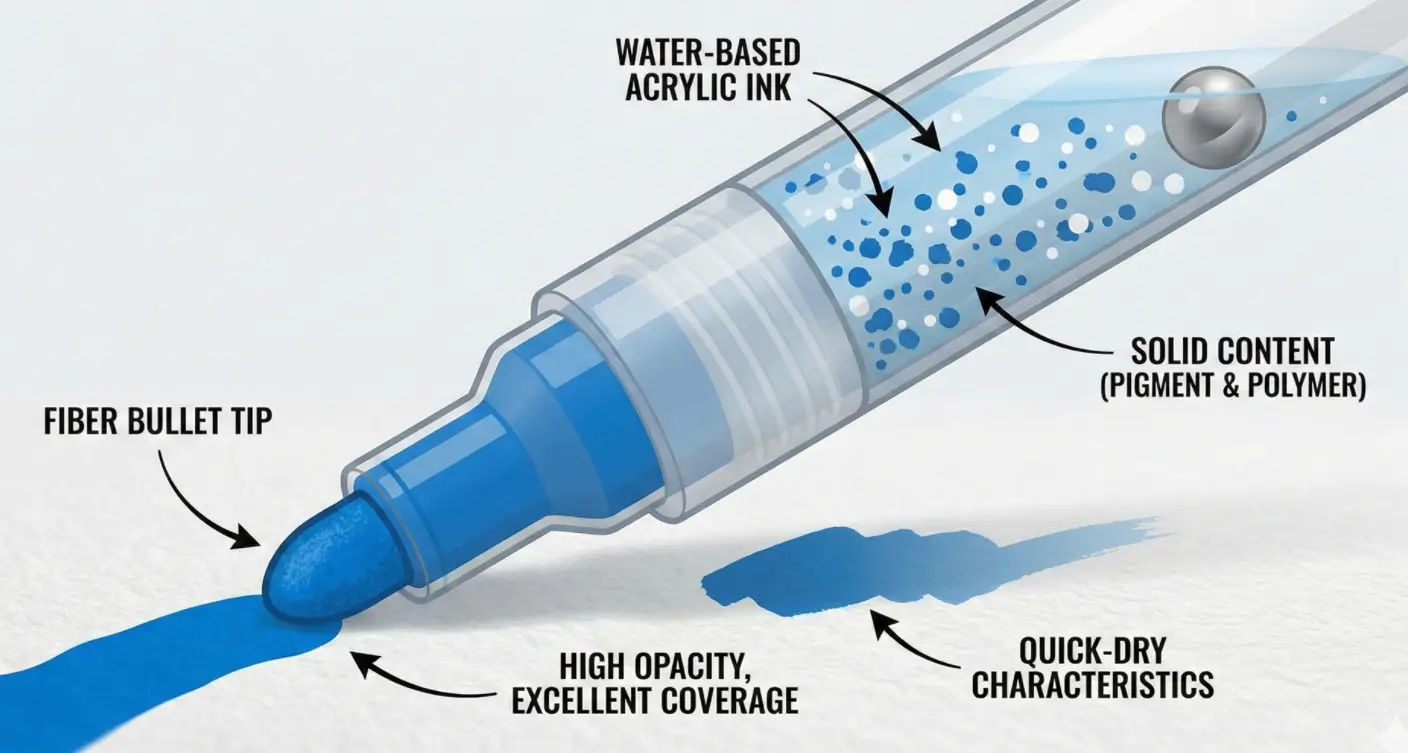

Acrylic paint markers are water-based pens filled with fluid acrylic paint that offer strong opacity and low odor for multi-surface creative work.

The ink is typically formulated with 35%–45% solid content, allowing it to cover dark surfaces with fewer layers.

Because they are water-based, they dry within 1–3 minutes, which supports layering without damaging the previous stroke.

Acrylic markers are commonly used on rocks, canvas, paper, fabrics, wood, and ceramics, making them versatile for DIY craft, school projects, and professional illustration.

Their safety profile is another strong advantage: reputable manufacturers provide EN71-3, ASTM D-4236, MSDS, and heavy-metal compliance reports, which are essential when selling into the EU or US.

From an export perspective, acrylic paint markers are also easier to pass marketplace audits on platforms such as Amazon and Walmart due to their non-toxic formulation and low VOC levels.

For buyers sourcing from China, acrylic markers are typically more stable in batch quality compared with solvent-based markers, as long as raw pigment quality is controlled.

Jaredrise Notes on Acrylic Marker Production

As a supplier producing acrylic markers for global markets, Jaredrise follows a batch-controlled process that checks viscosity stability, tip abrasion resistance, and solid-content consistency. Production includes:

- Solid content (SC) check: Target value 38%–42%

- Viscosity range: 3800–5200 cps for smooth flow

- Tip durability: ≥ 500 continuous strokes without fraying

- Safety compliance: EN71-3, ASTM D-4236, MSDS

- Export markets: North America, EU, Australia

These parameters are included because overseas buyers often request quantifiable specifications, especially when comparing suppliers or preparing for third-party testing before shipment.

What Are General Paint Markers?

General paint markers are pens that may use acrylic, oil-based, solvent-based, or pigment-ink formulations, creating wide variations in opacity, texture, and safety.

Oil-based paint markers are known for permanence and abrasion resistance, but they usually contain solvents that produce a stronger smell and longer drying time.

Solvent-based markers sometimes include chemicals such as xylene or toluene, which require ventilation and proper handling.

Paint markers often perform better on metal, plastic, glass, and industrial surfaces, especially when the objective is permanence and weather resistance.

Drying time ranges from 3–8 minutes, depending on formulation.

Because of the diversity in formulas, quality consistency varies significantly between suppliers, and buyers must verify the ink composition, VOC levels, and whether the product meets required safety standards.

For buyers seeking long-term durability or industrial marking performance, oil-based paint markers deliver stronger adhesion, but they require stricter safety checks and are less suitable for children or classrooms.

Jaredrise Notes on Paint Marker Variations

In paint markers, Jaredrise categorizes products by ink base to help buyers match markers with their intended surfaces:

- Oil-based industrial markers for metal and plastic

- Acrylic-based paint markers for mixed-media application

- Permanent solvent markers for construction or warehouse use

Quality consistency is evaluated through adhesion testing (ISO 2409), solvent evaporation rate checks, and VOC content measurement.

Buyers often request data on odor intensity and adhesion because actual performance differs widely across factories.

Key Differences: Acrylic Markers vs Paint Markers

The primary difference between acrylic markers and paint markers lies in ink composition and safety, which influences their opacity, odor, and application scenarios.

Acrylic markers use water-based acrylic paint and are typically safer, while paint markers may use solvents for stronger durability.

Major Differences at a Glance

Ink formula:

- Acrylic → water-based

- Paint marker → oil / solvent / acrylic / pigment-ink

Opacity:

- Acrylic → strong, covers dark surfaces

- Paint marker → varies by formula

Layering:

- Acrylic → excellent for multi-layer artwork

- Paint marker → oily formulas are harder to layer

Safety:

- Acrylic → usually non-toxic

- Paint marker → may contain solvents

Drying time:

- Acrylic → 1–3 minutes

- Paint marker → 3–8 minutes

Surfaces:

- Acrylic → rocks, canvas, fabric, wood

- Paint marker → metal, glass, plastic

Children-friendly:

- Acrylic → yes, if certified

- Paint marker → depends on solvent content

This structured comparison meets Google’s preference for list-based explanations and clear definitions.

How to Choose the Right Marker When Buying from China?

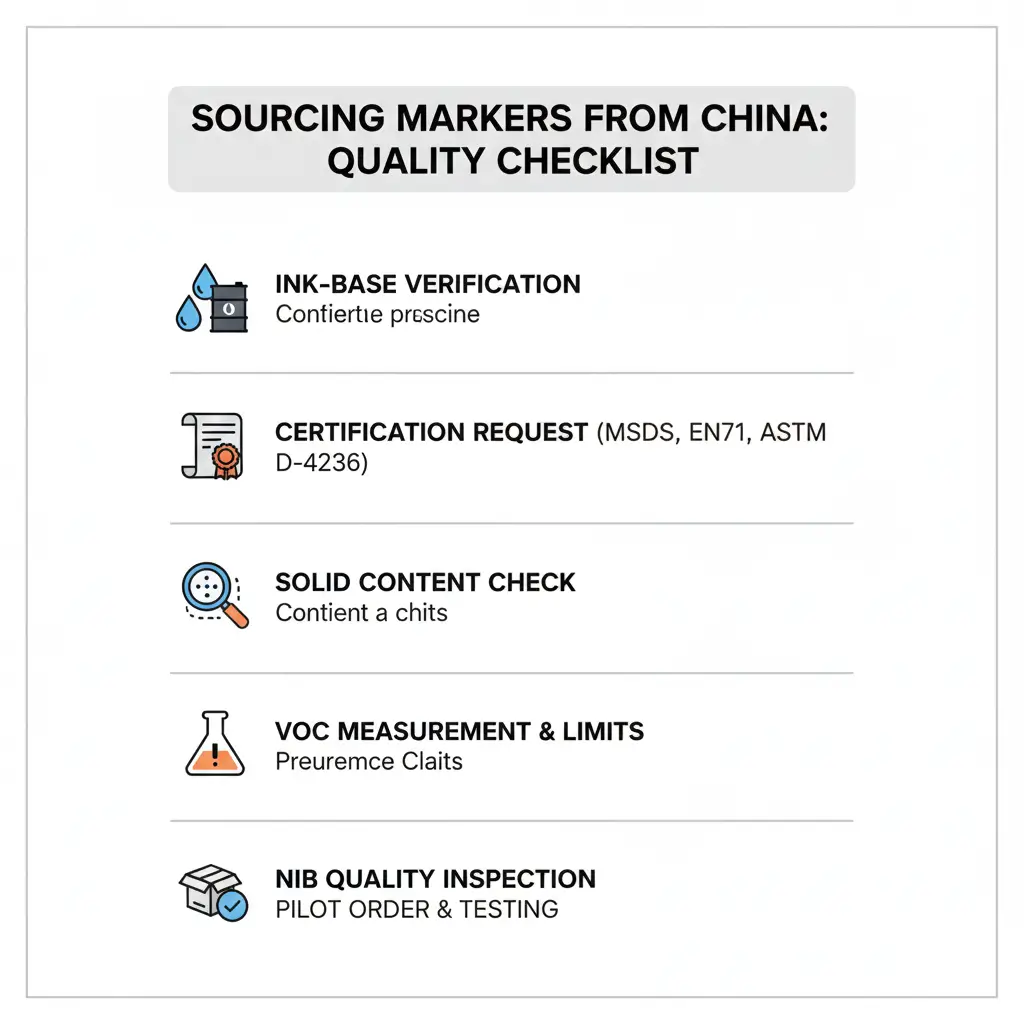

Choosing between acrylic markers and paint markers depends primarily on your intended application, safety requirements, and conformity needs for your target market.

Buyers with specific performance goals should rely on measurable quality indicators rather than relying solely on sample appearance.

Practical Selection Checklist

- Confirm the ink base first:Most sourcing mistakes happen when “paint marker” is used as a generic term. Always request ink-base confirmation: acrylic, oil-based, or solvent-based.

- Ask for visible certifications:For the EU/US, the minimum requirement is EN71-3, ASTM D-4236, MSDS, and heavy-metal test reports. Low-cost suppliers may skip these.

- Check solid content for acrylic markers:Higher solid content (35%–45%) usually means better opacity and smoother coverage.

- Evaluate tip quality:A stable marker requires a nib that does not fray or deform. Tip durability directly influences user experience.

- Verify VOC levels for safety:Child-safe products typically need VOC < 300 ppm. Many low-tier solvent markers exceed this.

- Request batch consistency checks:Even large factories can have variations, so ask for batch-level test results, not only factory-level certification.

- Begin with a small pilot order:A 100–300 set pilot run reduces risk and provides reliable feedback before scaling production.

These steps reflect what experienced importers do in real procurement processes.

Safety and Non-Toxic Certifications You Should Verify

Non-toxic and compliance documentation is essential when exporting markers to regulated markets.

The key certifications include:

- EN71-3 – Europe Toy Safety (heavy metals & chemical limits)

- ASTM D-4236 – US Art Material Safety

- MSDS – Material Safety Data Sheet

- RoHS – Restriction of Hazardous Substances

- REACH SVHC – List updated every 6 months

Jaredrise Compliance Capabilities

Jaredrise provides up-to-date test reports through SGS / Intertek depending on buyer market requirements.

Compliance is not treated as a single document but as a recurring process that includes raw-material selection, batch-level sampling, and VOC monitoring.

This helps buyers avoid customs delays or regulatory issues when selling on marketplaces.

Which Marker Is Best for Your Project?

The best choice depends on surface type, durability needs, and user group, and understanding common scenarios helps buyers avoid mismatched purchases.

- DIY craft, rock painting, children’s sets → Acrylic Markers

- Metal and industrial marking → Oil-Based Paint Markers

- Glass and ceramic designs → Acrylic or oil-based depending on permanence needed

- Outdoor labeling → Oil-Based for stronger weather resistance

For online sellers, acrylic markers typically generate fewer return requests because they have lower odor, better color consistency, and safer formulations.

Why Many Buyers Choose Jaredrise as a Marker Supplier ?

The primary reason customers work with Jaredrise is the expectation of consistent specifications, clear documentation, and predictable lead times rather than promotional claims.

Buyers often look for suppliers that can maintain batch-level consistency and transparency about raw materials.

- Founded: 2018

- Product Focus: Acrylic markers, paint markers, dual-tip art markers

- Certifications: EN71-3, ASTM D-4236, MSDS, RoHS

- Manufacturing Capabilities:Solid content control 38%–42%,Viscosity stability testing per batch,Fiber-nib abrasion tests

- Export Markets: United States, Germany, Canada, Japan

- Typical Client Profile: DIY brands, art-supply importers, Amazon private-label sellers, educational distributors

- Operational Strength: Structured documentation, transparent QC process, support for small pilot orders before mass production

This information is positioned to support informed decisions rather than push sales messaging.

Conclusion

Acrylic markers offer safer, water-based performance with strong opacity, while paint markers vary widely depending on their oil-based or solvent-based formulations.

Acrylic markers are generally more suitable for DIY, crafts, and children, whereas paint markers excel in durability on metal and industrial surfaces.

When sourcing from China, buyers should prioritize ink-base confirmation, visible non-toxic certifications, and measurable quality indicators such as solid content, VOC levels, and tip durability.

For importers seeking reliable specifications and stable production, Jaredrise provides structured compliance, batch-level inspection, and manufacturing transparency tailored to global markets.