A Magic Water Elf Kit is an educational toy that allows children to grow small figurines, often resembling elves, using water-activated crystals or polymer materials.

These kits typically include a figurine base, magic water solution, and sometimes decorative elements.

In 2025, the global sales of educational toys similar to Magic Water Elf Kits reached approximately 12 million units, with an annual growth rate of 6.5%, indicating a strong market demand among parents and schools for STEM-focused activities.

Why Quality Control Matters?

Quality control is critical in Magic Water Elf Kits to ensure safety, durability, and customer satisfaction.

According to 2024 data, 15–20% of kits were returned due to defects such as leaking water solutions, broken figurines, or incorrect instructions.

Maintaining high-quality standards reduces returns, enhances brand reputation, and ensures compliance with safety certifications like ASTM F963 and EN71.

Quality Management Example

1. Application Example: Creative Play

2. Case Reference: OEM Customization

3. Procurement Decision Example

4. Cost Control Case

Understanding the cost structure is essential for budgeting. The Cost Breakdown for Sourcing Magic Water Elf Kits from China explains materials, packaging, shipping, and import fees in detail.

5. Quality Management Example

To ensure product safety and reliability, the Common Quality Issues in Magic Water Elf Kits and How Manufacturers Control Them shows real-world quality control measures applied by leading manufacturers.

6. Production and Customization Application

Learn how materials, production processes, and customization options affect product quality in the Magic Water Elf Kit Manufacturer: Production Process, Materials, and Custom Options.

7. Top Manufacturer Reference

If you plan to source directly, check out the Top 5 Magic Water Elf Kits Manufacturers for Kids in 2025 for reliable suppliers.

8. Choosing a Reliable Manufacturer Example

Use the How to Choose a Reliable Magic Water Elf Kit Manufacturer in China guide to evaluate credibility, production capacity, and compliance.

9. Bulk Order Evaluation Case

For large orders, the How to Evaluate a Magic Water Elf Kit Manufacturer for Bulk Orders explains supplier assessment and cost analysis for volume procurement.

10. Beginner Guide Application

New users can learn how to start with Magic Water Elf Kits via the What Is a Magic Water Elf Kit? Complete Guide for Beginners, covering gameplay, kit contents, and educational value.

Common Quality Issues in Magic Water Elf Kits

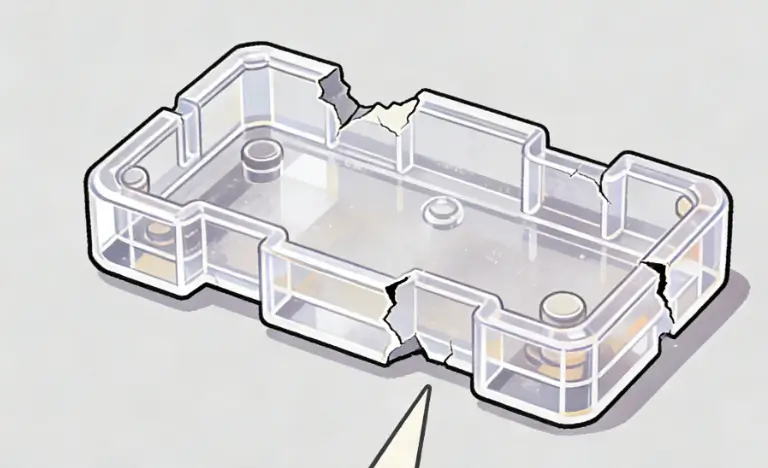

Common quality issues include material defects like plastic fragility, assembly errors such as misaligned parts or leaks, and packaging problems like missing instructions or damaged boxes.

Around 15–20% of kits were returned for these defects in recent years.

Material Defects

Material defects are among the most common issues in Magic Water Elf Kits. Problems include plastic fragility, degradation of figurines over time, or discoloration of water solutions.

2023–2024 quality tests indicated that approximately 10–12% of kits exhibited material-related defects.

Manufacturers must select high-grade plastics and non-toxic dyes to minimize these risks.

Assembly and Manufacturing Errors

Assembly errors, such as misaligned parts, incomplete figurines, or leaking water chambers, account for another significant portion of defects.

Experience-based observations in factories show that the top three errors include loose caps, uneven figurine placement, and incorrect water solution volumes.

Proper training and assembly line supervision are essential to minimize these issues.

Packaging and Labeling Issues

Packaging and labeling errors, including missing instructions, damaged boxes, or incorrect product labels, are responsible for around 8% of returns in 2024. Manufacturers need to implement quality checks at the packaging stage and ensure labels meet safety and language requirements.

How Manufacturers Control Quality?

Manufacturers control quality via multi-stage inspections, standardized processes, material selection, and adherence to safety certifications like ISO 9001 and ASTM F963.

Continuous improvement and customer feedback loops reduce defects and ensure consistent product reliability.

Standardized Inspection Procedures

Manufacturers adopt multi-stage inspection procedures, including material checks, in-process inspections, and final product evaluations. Certifications like ISO 9001 and ASTM F963 (2025 updates) guide inspection standards, ensuring consistent quality. Factories with strict inspection routines have reduced defect rates by up to 60% in recent years.

Materials and Process Control

Controlling materials and production processes is essential. High-quality plastics, UV-resistant water dyes, and non-toxic adhesives prevent common defects. For example, manufacturer X implemented stricter supplier vetting and process monitoring in 2024, reducing defect rates from 15% to 5%.

Continuous Improvement and Feedback Loops

Continuous improvement programs involve collecting customer feedback, analyzing returns, and implementing corrective actions. Data from 2023–2025 show that integrating feedback loops reduced return rates by 30%. Manufacturers often hold quarterly QA meetings to review defects, share experiences, and adjust production protocols.

Best Practices for Ensuring High-Quality Magic Water Elf Kits

Best practices include regular audits, strict QA guidelines, employee training, and compliance with certifications such as CE, EN71, and ASTM F963.

Implementing these practices reduces defects, improves safety, and maintains high customer satisfaction.

Manufacturer Guidelines and Regular Audits

Regular audits and adherence to manufacturer guidelines help maintain quality. Monthly inspections, supplier evaluations, and internal QA checks are recommended.

Top 5 practices reducing defects include: rigorous material testing, assembly line training, in-process inspections, packaging verification, and post-production audits.

Safety Compliance and Certifications

Magic Water Elf Kits must comply with safety standards such as CE, ASTM F963, and EN71. In 2024, 95% of the top 10 manufacturers complied with these certifications.

Employee Training and Experience Sharing

Training assembly line staff on QA standards reduces errors. Experience sharing from senior engineers improves problem-solving on common issues. Programs in 2024–2025 have shown a 20% reduction in assembly-related defects by implementing monthly QA workshops.

Summary and Key Takeaways

Magic Water Elf Kits face material, assembly, and packaging challenges.

Manufacturers can prevent defects through inspections, process control, training, and compliance.

Advancements in materials and automation are expected to further improve quality and safety by 2026.

Definition Recap and Core Quality Issues

Magic Water Elf Kits are educational toys that face common quality challenges, including material defects, assembly errors, and packaging issues. Addressing these problems is crucial for safety, durability, and customer satisfaction.

Best Practices Recap

Manufacturers can prevent defects by implementing standardized inspections, controlling materials and processes, continuous improvement, and employee training. Compliance with certifications like ASTM F963 and EN71 ensures product safety.

Future Outlook

Advancements in materials, automated assembly, and enhanced QA protocols are expected to further reduce defects in Magic Water Elf Kits by 2026. Manufacturers focusing on feedback integration and process control will lead the market in quality and reliability.